Continuous filter for plastic extruding machine

1.0~10000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHZ |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Purification Filter |

| Brand Name: | DEAO |

| Belong to: | spare parts of plastic extrusion machine |

| Function: | polymer melt filtration |

| suitable materials: | almost all polymers PP/PE//ABS/XPS/WPC |

| Application: | pipe/sheet/plate/tube/compounding/blow film/cast film/fiber and so on |

| Type: | different types to be match with extruders |

| high pressure resistant: | 400bar |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40days after receiving down payment |

Product Description

Continuous filter for plastic extruding machine

The manual screen changer now is still widely used in all over the world, many people even do not know that there is a kind of melt filter/screen changer called hydraulic screen changer,non-stop screen changer, continuous screen changer, automatic screen changer. But when they get to know that the continuous screen changer can realize that no need to stop the extruder when the operator changing the screen, they are very happy.

Here is an example, one of our customers, the information of his extruder

1,screw diameter: 72mm twin screw

2,raw material: PET

3,product: PET strap

4,curent filter type: no screen changer just a breaker plate with screen between the die and screw

5, the current screen size: diameter 160mm

6, screen change interval: about 1 hour.

7,output:220kg/h

According to the information about the extruder, we recommend our double piston double working position screen changer DHZ-2-160 for him

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |

The double piston double working p[osition screen changer consists of the main body of the scren changer, the hydraulic power unit and electrical controlling pack.

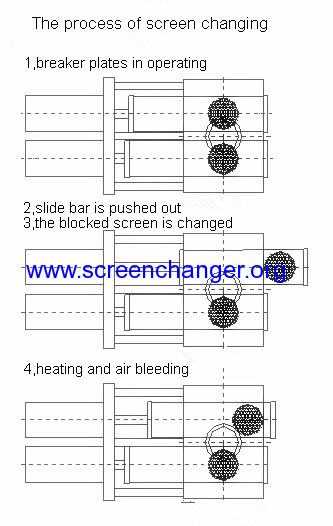

1, in the normal condition, the two filter screen on the two slide bar are in the working position, the material melt is dvided into two chanel .

2, when the alarm device is alarming , remind us to change the screen, one piston is pushed out and the blocked screen will be replaced by a new one, then the slide bar is pushed back, the exhaust system begin to work at the same time.

3, then the other screen is replaced as the same way as before. this processing is cycled

Application

1. Used for the production of plate, sheet, cast film, pipe, granulation and so on.

2. Applicable to the production line of colossal, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture, filtering screen replacement available without machine halt.

Here i show some pictures of the double piston screen changer