plastic melt filter-hydraulic screen changer

1.0~10000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

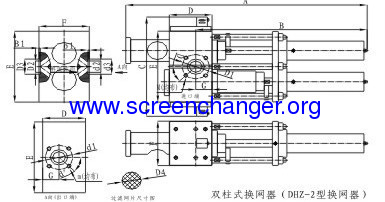

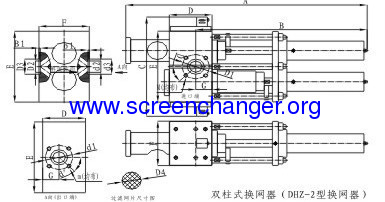

| Model No.: | DHZ |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DEAO |

| Belong to: | spare parts of plastic extrusion machine |

| Function: | polymer melt filtration |

| suitable materials: | almost all polymers PP/PE//ABS/XPS/WPC |

| Application: | pipe/sheet/plate/tube/compounding/blow film/cast film/fiber and so on |

| Type: | different types to be match with extruders |

| high pressure resistant: | 400bar |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40days after receiving down payment |

Product Description

plastic melt filter-hydraulic screen changer

This double working position hydraulic screen changer is designed to work with two channels inside. It contains two screens that work at the same time: one screen works, while the other one is changed during the process of screen replacements, thus the replacement without machine halt is ensured and no interrupt of material fluid and of production will occur. Therefore, the screen changer meets the customers' requirement of higher productivity and better quality.

ADVANTAGES

• Processing capability for all thermoplastic materials

• Optimal flow channel geometry - short dwell time

• Low pressure build-up – minor thermal change of the melt

• Freedom from any clearances accelerates change of material and colors

• Innovative production techniques and thermal treatment methods

• High operational reliability and long service life

• Low investment costs, rapid amortization

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Coating (Hot melt adhesive)

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Pelletizing (strands and underwater)

Recycling of most polymers

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |