China Progressive Stamping Tool

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Shanghai Stamping Die |

Product Detail

| Model No.: | HPT-X50 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Vehicle Mould |

| Product Material: | Steel |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Item: | China progressive stamping tool |

| Parts material: | Cold sheet, SS, SPCC, SGCC etc. |

| Tool material: | SKD11, DC53, D2 |

| Tool parts: | PUNCH, MISUMI, Dayton |

| Tool life: | 1,000,000 hits |

| Delivery: | 40 days for tool machining |

| Production Capacity: | 50 sets per month |

| Packing: | wooden cases |

| Delivery Date: | 40 days |

Product Description

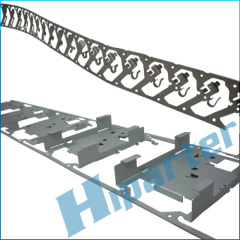

Details for China Progressive Stamping Tool

Drawing acceptable | 2D: .dwg, .pdf, .dxf or others |

3D:.stp, .step, .x_t, .igs, .prt, or others | |

Parts application | Progressive stamping production |

Tool type | Progressive stamping tool |

Parts material | Cold sheet, SS, SPCC, SGCC etc. |

Tool material | SKD11, D2, SKH-9, DC53 etc. |

Tool life | more than1 million hits |

Delivery time | within 40 days after tool structure confirmed |

Advantages for China progressive stamping tool

1) reasonable China progressive stamping tool structure

2) Tracking every steps for manufacturing the tools, building report sent every week.

3) Feedback any question or problem in 24 hours

4) Advanced manufacturing, measuring and testing equipment

5) Samples inspection and delivery before shipping the China progressive stamping tools

Company information

1) Year of 2003 built in Qingdao, Shandong Province

2) manufacturer for China progressive stamping tools

3) 55 sets of machines for China progressive stamping tools making, including CNC, WEDM-LS, Milling machine, Grinding machine, press machines for tool trial and so on.

4) Quality control system: ISO9001:2008 certificated by SGS, the tool life can be guaranteed.

5) PUNCH, MISUMI, Dayton standard parts, the dies and inserts can be maintained easily.