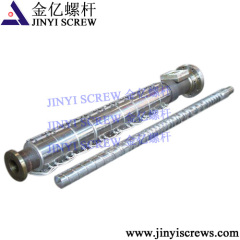

Extrusion Double Sided Screw Cylinder

100.0~10000.0 USD

| Min. Order: | 1 set |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000 units/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Double Screw Barrel For Pipe Production Line, PA Injection Screw Cylinder, Pet Blow Moulding Machine Screw And Barrel, Conical Screw For PVC Pipe And Profile, Plastic Injection Molding Machinery Screw Barrel |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | Shenglong |

| Steel material: | 38CrMoAla,SACM645,SKD61,GH113.etc |

| Steel Hardness after hardening&tempering: | HB280-320 |

| Nitriding hardness: | HV900 |

| Nitrided case depth: | 0.45-0.7MM |

| Surface Roughness: | Ra0.4 |

| Design: | Good plastification and mixing effect |

| For what type plastic machiner: | extruder machine |

| Alloy: | Fe-based,Ni-based,Tungsten carbide |

| Raw material: | pvc pipe,profile |

| Production Capacity: | 3000 units/month |

| Packing: | Wooden case |

| Delivery Date: | 30 days |

Product Description

Extrusion Double Sided Screw Cylinder

Extrusion doublesided screw cylinder

Twin screws

Extrusion doublesided screw cylinder

If you do not see the particular model you are looking for in our website, please give me a call orEmai to discuss your needs. In most case we can provide you with a complete solution to meet your

demands.

Extrusiondouble sided screw cylinder | |||

Diameter | Φ15mm-Φ350mm | Designing | ConicalScrew structure and compression ratio can be designed according to different products &differentmixtrues. |

Specifications of standard for extruder conicalscrew | 45/90, 51/105, 55/110,65/132, 80/156, 80/172, 92/188. | Advantages of extruder conical screw | 1.Advanced Nitriding Technology 2.Anti-corrosion and Wear-resisting Duplex Metal SprayingTechnoloy 3. we uses special alloy powders beingsprayed and welded on the screw's ridge,and uses differentalloy and welding methods for the screw of differentfunctions. |

Materials | 38CrMoAlA (JIS SACM645) SKD61 | Application | |

Nitride Case Depth | 0.5mm-0.8mm | Technology | 1)Longer time Gas Nitriding treatment 2)special anti-wear & abrasion alloy (bimetallic) 3)tungsten carbide 4)cobalt base alloy 5)stainless steel 6)Gh113 nickel based alloy |

Nitride Hardness | 950-1060HV | Packing | Wrapped up by film in wooden |

Nitride Brittleness | ≤Grade One | Payment Term | T/T , L/C ,WesternUnion |

Surface Roughness | Ra0.4um | Delivery Term | 15-30 working days |

Screw Straightness | 0.015mm | Port Departure | Shanghai/Ningbo |

Alloy Hardness | HRC58-62 | Min. Order | 1 set |

Alloy Depth | 1.5mm-3.5mm | Common Nitrided:2.5-4years Bimetallic: much longer lifetime. | |

Twin screws

About Shenglong Machinery

- Our Strength: We have an experience of more than 20 year of manufacturing anddesigning Plastic machines, varied Screws and Barrels and spares.Weconcentrate on improving quality, updating design and enhancing service.

- Our products: Screws Barrels for Injection, Extrusion, and Blow Moldingapplications; relevant accessories(such as die head, gearbox, filterscreen changer and so on); plastic processingmachinery.

- Location advantage: located in China'sScrew Town- Jintang Townin Zhoushan City,near to Ningbo Port and Shanghai Port.

- Market areas: global sales network reaching South America, Eastern Europe,Southeast Asia, Africa, Oceania and the Middle East.

- We promise: We assure the customer benefits, We provide competitive price, WeEmphasis On Cooperation.