Nitride double parallel screw cylinder for recycling extrusion

1000.0~20000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

| Model No.: | QY-130325G |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | QunYing |

| Power: | 4-150KW |

| Base Material: | 38CrMoAlA,DC5,D2,SACM645,ect. |

| Bimetallic Screw Process: | Spray Welding |

| Bimetallic Barrel Process: | Centrifuge Casting |

| Nitrided layer depth: | 0.5-0.8mm |

| Surface roughness:: | Ra0.4um |

| Bimetallic: | Fe-based,Ni-based,Tungsten Carbide(Wc) |

| Application: | Proflie,PVC/PE/PP Granules/profiles/Foaming... |

| End products: | WPC, proflie, pipe film etc. |

| Desigh: | As BAUSANO/KraussMaffei/Cincinnati/Battenfeld... |

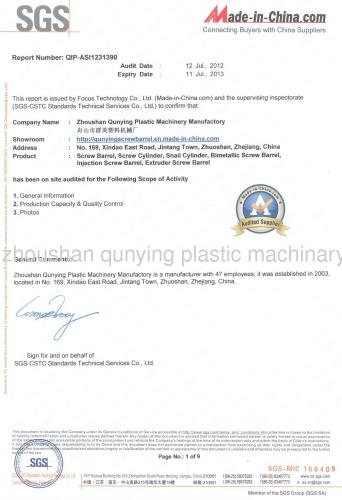

| Certificates: | GB/T19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 1000 sets per month |

| Packing: | Wooden Case (Exported Standard) |

| Delivery Date: | 25 Days |

Product Description

Nitride double parallel screw cylinder for recycling extrusion

Double parallel screw cylinder | |

Screw Diameter : 55/2,65/2,70/2,80/2,88/2,90/2,100/2,110/2,130/2... | |

Plastic processed : PVC PP PE HDPE LHDPE PET WPC, etc. | |

Technical Parameter | |

Nitride Case Depth | 0.5mm-0.8mm |

Nitride Hardness | 950-1150HV |

Nitride Brittleness | ≤Grade One |

Surface Roughness | Ra0.4um |

Screw Straightness | 0.015mm |

Alloy Hardness | HRC58-75 |

Alloy Depth | 0.8mm-3.5mm |

Chromium Coating Thickness | 0.025~0.10mm |

Material & Technologies | |

SKD61(H13) | Quality 38CrMoAIA (41CrAIMo7) |

Gr12MoV | Quality Duplex Stainless Steel |

42CrMo | Quality Powder Metallurgy Materials |

40Cr | Hard Metal Cold/Thermal Spraying Technology |

Zinc 3# Steel | Advanced Nitriding Technology |

Anti-corrosion and Wear-resisting Duplex Metal Spraying Technology | |

Technological Process | |

1.Rough Machining | 2.Quenching and Tempering |

3.Finish Machining | 4.Nitriding |

5 Sprey conating Bimetallic | 6.Screw polishing |

REMARK:

- We are able to take mapping, design for clients and make products as per customer's drawing or sample excellently , also can help customer to repair the old screw and barrel by useing bimetallic-alloy process

- Screw structure, compression ratio and material can be changed according to different products and output.

- Technological Process can be chosed acoodring to your requirments.

- Commonly used materials: 38crMoAIA, nitrogen treatment . Various high quality alloy steels , according to different usage, the choose for alloy is different, some require for abrasion-resistant while some require for corrsion-resistant. For standard, we have Fe-based, Ni-based, W2C alloy,Tunsten alloy etc for choice

The foreign material we used as following:

1. Germanysteel, GH113 ,2250 ,2842 ,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

2. USA steel, P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

3. Sweden steel, 718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

4. Australia Steel, M202,M300,W302,K460,W300,K900,K100,W321

5. Hardnesssteel, YG6X,YG 6A,YG 6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

6. Japan Steel, SKT 4,YXM 4,YXM 42,SNC 815,SK -3,SKS 3,and etc.

Our Certificates:

Factory pics:

Quality Certificate:

•100%Quanlity Inspection

As the screw and barrel are the important parts for plastic extruders and injection molding machine,they affect the machine performance and quality directly,therefore,QunYing established quality control system strictly as ISO 9001:2008 International Quality System, our every production process is under strict inspection , Those provides solid foundation for our quality products!What we need to do is to make sure best quality of each screw and barrel.Till now,our screw and barrel has been sold to more than 40 countries in the world and enjoy a good reputation by our customers!

Products sales network:

About us

QunYing Screw is leading supplier of SCREW and BARREL in china,including designing,manufacturing and sales for these products,we can make any specification of extruder screw barrel and injection molding screw barrel for Haitian,Demag,Engle,Nigrobossi,KMD,NPM,BOY,HUSKY, Nippon Steel, Toshiba, Nissei, Mitsubishi and etc. We also can supply all types of screw and barrel according to your different requirements.

What is our advantage:

First:Cretive in designs,our desinging team is very strong,since we have unique culture to motivate them,in order to meet requirement,we work closely to our customer and market!

Second:We have 10 years' experience of manufacturing varied screws, barrels and spares.We are keeping improving our production stytem day by day on the delievey,quality control,all the efforts have improved the customers satisfaction!

Third:We are located in China's screw Town-Jintang,Town in zhoushan city,near to Ningbo Port and Shanghai Port!

Finally,We assure the customer benefits,we supply best quality and competitive price,also best customer service!