box feeder Powder Coating Gun

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200pieces per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | CL-151S-B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Others |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Painting / Powder Coating |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Aluminum |

| Brand Name: | COLO |

| Electrostatic Powder Coating System: | Pulse plus intelligent |

| coating: | powder coating |

| Warranty: | 12months |

| Weight: | 60kgs |

| Delivery way: | by air or by sea, according the quantity |

| Delivery time: | 3-5days after payment |

| Payment: | T/T |

| Features: | for all kinds workpiece |

| Dimension(L*W*H):: | 118CM*79CM*73CM |

| Certification: | CE |

| Production Capacity: | 200pieces per month |

| Packing: | wood box or carton box |

| Delivery Date: | 3-5days |

Product Description

box feeder powder coating machine

CL-151S-B is a copy model Manual powder coating equipment, box feed easy to chage colors

Host: colo-STAR, intelligent

Electrostatic spraying: COLO-SELECT manual spray gun

Powder barrels: spraying powder barrels of 50 l

The machine warranty for one year, life-long maintenance

Suitable for spraying complex workpiece, high efficiency greatly save powder waste and work time

Suitable for large factory export products processing user use

High-end quality and favorable price

manual coating equipment - spare parts list

1Wheel shaft

2Rubber wheel - Ø 200 mm

3Lock washer - Ø 26 mm

4Swivel wheel - Ø 50 mm

5Spacing ring

6Rubber damper- Ø 20x25 mm, M6/2a 43sh

7Fluidizing/suction unit (see corresponding spare parts list)

8Stop plate

9Countersunk Allen screw - M6x40 mm

10Countersunk Allen screw - M6x20 mm

11Handle bar

12CG07 gun control unit - complete (see corresponding user manual)

13Hose holder

14Hexagon shakeproof nut - M6

Cable connection fitting for vibrator cable - M16/1/6-10.5 mm, brass (not shown)

17Cable plug - 4 pins, male

18Countersunk Allen screw - M6x30 mm

19Grounding cable - complete

20Plastic hose - Ø 8/6 mm

21Vibrator motor - 220-240 VAC, 50 Hz

Vibrator motor - 120 VAC

22IG02-V Injector - complete (see corresponding user manual)

23Gun retainer

24Spare parts set - MB02, consisting of:

Insert sleeve PTFE

Injector plug gauge

Fluidizing pad - 1/8"a

O-ring - Ø 16x2 mm

Fuse - 4 AT

Fuse - 2 AT

Fuse - 0.1 AT

Cable tie - L=100x2.5 mm

25Ribbed cylinder screw - M10x20 mm

26Hexagon ribbed cylinder screw - M8x16 mm

27Short instruction sheet OptiStar CG07

28Program table sheet OptiStar CG07

Color change

When a color change takes place, the individual components of the ma-

nual coating equipment must be cleaned carefully. Thereby, all powder

particles of the former color must be removed!

Procedure:

1. Clean the fluidizing/suction unit

2. Clean the powder hose:

Strip the powder hose from the hose connection on the

injector

Point the gun into the booth

Blow through the hose manually with a compressed air

gun

Fit the powder hose again to the hose connection on the

injector

3. Dismantle and clean the powder gun (see therefore the user ma-

nual of the OptiSelect manual powder gun)

4. Clean the injector (see therefore the user manual of the OptiFlow

injector)

5. Prepare the manual coating equipment with new powder for

start-up

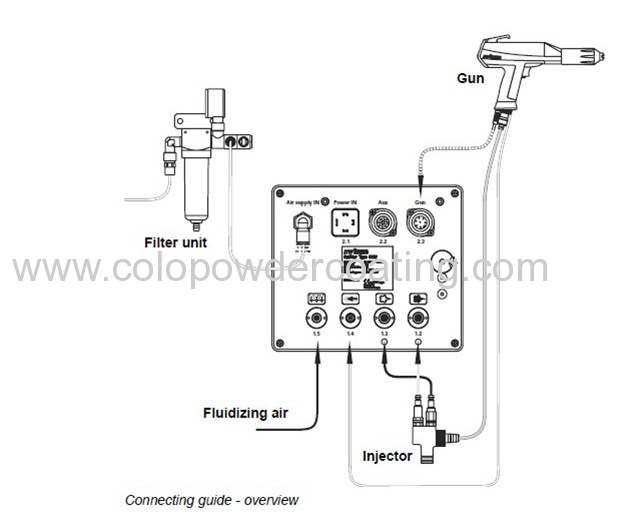

Connection guide

You also could know how to connect from the video.

powder coating gun

Good for coating workpieces with complicated shapes,1.light weight, 2. highly efficient working, 3. 0-100V output in the gun

Technical parameter(high voltage module):

Input power voltage: Max. 20V (peak-peak value)

Input current: Max. 0.8A

Frequency: 9-30KHZ

Output power voltage: Max. DC-100KV

Output current: Max. 150uA

Polarity: Negative

Weight: 500g

The GUN:

Integrated controls on the gun

POWDER FLOW AND HIGH VOLTAGE:

Adjustable parameter settings: Optimum electrostatic charge

whatever the part to coat and type of powder

Integrated controls on the gun

4 basic preset adjustments in memory

Application with round spray nozzle:

• Increases particles charge

• Better wrap round and higher transfer efficiency

• Very homogeneous pattern on complex or simple shaped parts.

Application with fan nozzle spray:

• Very good coverage and efficiency and flat parts

• Easy coating in deep recesses

• Very good penetration in complex parts.

Application adapted with round or fan spray nozzle:

• Re-coating

• Large thickness of powder (> 100 μm)

• Low conductive substrates (glass, wood,...).

Application adapted with round or fan spray nozzle:

• Suitable for metallic powders

• The voltage (kV) can be increased to improve the transfer efficiency.

Why doesn't the gun control show any Kv reading?

Possible Causes:

Loss of power to the unit.

Failure of LED driver (circuit board)

Internal gun failure (cascade)

Factory:

Packing & delievry

Show

We produce electrostatic powder coating equipments, automatic reciprocator, powder spray booth, curing oven and spare parts for G ,W , N , K famous brand in china for many years ,COLO brand equipments have already exported into more than 90 countries , we promise good quality and after-sale service all the time . We got used to do business by the price of FOB Ningbo or Shanghai,besides we also accept the exceptions for the clients' request. Deliver time will according to your order items and quantity.

Any inquiry, please contact: