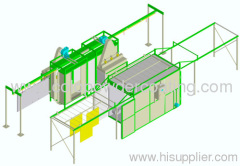

powder Coating Production Line

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200pieces per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | colo |

| product max size: | L500mm*W600mm*H900mm |

| product max weight: | ≤30Kg |

| Conveyor chain single hanging weight: | 20 Kg |

| Design line speed and adjustable line speed: | 1.5m/min (0.3m-3.6m/min) |

| coating area: | surface |

| Drying tunnel heating: | electric heating |

| Compressed air: | the users themselves, freeze-drying, moisture content <1.3g/m3 oil content <1PPM |

| Energy: | (1) three-phase four-wire (380V). With ground wire a 2. Compressed air |

| Production Capacity: | 200pieces per month |

| Packing: | wood box or carton box |

| Delivery Date: | 15days |

Product Description

Specifications

We have finished more than hundreds of projects. Under many years effort, our company has won customers trust and support, Product Description

Powder coating line

We provide professional service of designing, manufacturing, assembling, commissioning and training in the coating industry. We have built up hundreds of turn-key projects in China and abroad.

Technical innovation never ends. We has developed the energy-saving heating system, multi-track one oven curing system, high-efficiency powder recycle system, simple and practical pretreatment system, compact powder coating system, power and free conveyor system. Which makes our company to the advanced position of coating industry.

Batch operation, or automatic conveyor zed operation, every powder coating system is custom designed to meet specific quality, performance, part size and production requirements. With over twenty years of experience, we are able to "Right-sizing" your powder coating system.

Details:

1) Pretreatment: Dipping pretreatment with overhead crane, or fully automatic spraying pretreatment

2) Conveying system: Closed-circuit conveyor, power and free conveyor, multi-track conveyor, and so on

3) Oven: Batch oven, combination oven, bridge oven, tunnel oven

4) Powder coating booth: Stainless steel booth or coated steel booth

5) Powder recycling facility: Cyclone system or cartridge filter system

6) Control system:

7) Spray gun and reciprocator