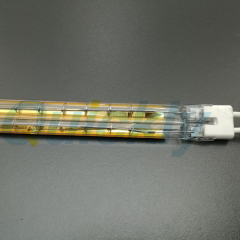

Infrared heat element for industrial oven

30.0~100.0 USD

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 3000pc per month |

| Place of Origin: | Chongqing |

Company Profile

| Location: | Chongqing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Infrared Burner, Infrared Catalytic Gas Burner, Bbq Infrared Burner, Industrial Infrared Burner, Infrared Heater |

Product Detail

| Model No.: | HD61 |

|---|---|

| Means of Transport: | courier, Ocean, Air, Land |

| Category: | Industrial Heater |

| Capacity Type: | Medium Duty |

| Brand Name: | Haodong |

| technology: | rara-earth catalytic combustion |

| Production Capacity: | 3000pc per month |

| Packing: | 2boxs per carton |

| Delivery Date: | in 1-15days |

Product Description

After coated with processed black rare-earth on the ceramic surface,the energy-transfer rate goes up greating,can save more than 10% energy than non-catalytic type.At the same time, it prolongs the use life of ceramic plate.

Material:

1. Shell: cast iron

2. Radiant part: cordierite honeycomb plates with black processed rare-earth catalyst coated

3. Nozzle: brass

4. Up cover: stamped iron

Working pressure: NG:2000~5000pa;LPG:2800~5000pa

Advantages:

1.Save above 30% energy than electric

1.Save above 30% energy than electric

2.High efficient: preheating up time can be reduced to under 30min

3.Eco-friendly :CO≤80ppm;NOx≤10ppm;CHx≤50ppm

4.Naturally aspirated burner,no need of accessories equipment,like air blower,fire chamber...

Applied Range Infrared catalytic gas burner is good choice industrial drying,baking or curing oven,especially in tunnel&converyor oven,saving production&equirpment cost,demand of space is small and easy to control......It martched with auto-igntion,safe controller and keep stable temperature.Now is already widely used industrial drying,especially in metal curing & food baking.......