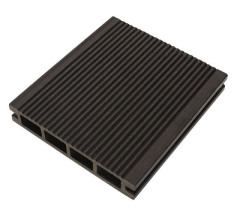

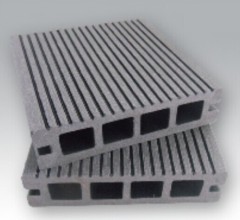

100x25 WPC Hollow Outdoor Decking

| Min. Order: | 1 container |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000tons per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM100H25-A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Pattern: | Others |

| Product Material: | Plastic |

| Technics: | Engineered Wooden |

| Function: | Waterproof |

| Usage: | Outdoor |

| Brand Name: | CXM or OEM |

| Material: | Wood Plastic |

| Color: | According to customers' request |

| MOQ: | one 20' container |

| Size: | 100*25 |

| Surface Treatment: | Thin tooth |

| Delivery Time: | Within 45 days |

| Process: | Extrusion |

| Payment Term: | T/T or L/C |

| Port of Loading: | Ningbo or Shanghai |

| Export Area: | Germany,England,France,Spain |

| Production Capacity: | 5000tons per month |

| Packing: | As per customers' request |

| Delivery Date: | 45 days |

Product Description

XM100H25-A WPC Hollow Outdoor Decking

***Definitions

Wood-plastic composite sheet is a major and made of wood (wood cellulose, vegetable cellulose)based

materials and thermoplastic polymeric materials (plastics) and processing aids, etc., and then mixed by

extrusion mold heating equipment the high-tech green materials, both the performance and characteristics

of wood and plastic, the new environmentally friendly high-tech materials can replace wood and plastic,

the English abbreviation of wood Plastic Composites WPC.

Wood floor is the floor with a wood-plastic composite materials, and timber have the same processing

characteristics, use common tools to sawing, drilling, on nails, very convenient, you can use the same as

ordinary wood. Meanwhile antiseptic properties of water and plastic wood texture with wood, making it an

excellent and very durable outdoor waterproof anti-corrosion materials.

***Performance of wood-plastic composite decking

The physical properties: strength, high hardness, non-slip, wear-resistant, no cracking,

no insects, small water absorption, anti-aging, corrosion resistance,anti-static and UV, insulation,

thermal insulation, fire retardant, resistant to 75 ℃ high and low temperatures of -40 ℃.

Environmental performance: Hazardous Substances ecological wood, green wood, renewable,

non-toxic substances, hazardous chemical ingredients, preservatives, formaldehyde, benzene and other

released, will not cause air pollution and environmental pollution can be 100% recycled recycling and re-processing, can also be biodegradable.

The appearance of texture: a natural appearance of wood, texture. Better dimensional stability than

wood, no wood knots, will not crack, warp, deformation, products can be made from a variety of

colors,surfaces without secondary leaching paint new Nagakubo also does not fade.

Processing performance: secondary processing of wood has, as sawing, planing, bonding, with nails or

screws, various profiles of standards, construction and installation quick and easy. By conventional

practices, can be processed into a variety of facilities and products.

***Society benefits

1. China's steel construction template huge amount of bamboo wood

As China and the construction of various projects launched again and again , to the rapid development

of industry templates . Expected in 2011 and 2012 China's construction industry template annual

production scale growth will be about 15% ; By the end of 2012, China's construction industry template

production will reach 220 million square meters or so .

2 .Building templates for amazing steel timber consumption , serious waste of resources

China's new annual production of steel formwork production was 39.7 million square meters of , if

convertedinto the equivalent weight of the amount of steel 27 Beijing Bird's Nest.

3 .Wood construction template replace traditional architecture template social

In our tackling climate change , promoting energy saving in the form of a template in the construction

industry, if I can use to replace steel and bamboo, wood materials , environmental benefits, social

benefits will be enormous . Currently building template above 200 billion in market demand , plastic

building templates in the next 3 to 5 years will account for 30% -50 % market share , output can reach

more than 60 billion , the market prospect is very broad.

WPC as the architectural template , you can greatly improve construction efficiency , shorten

construction time. Wood than the traditional template template using a single integrated cost savings

of about 30% ,ancillary costs can be reduced by about 40 percent , directly reduce project construction

costs nearly 5%.Sau plastic sheet has many advantages green, low-carbon economy and so on.

***The information of wpc decking

Type | |

Place of Origin | Zhejiang, China (Mainland) |

Model Number | XM100H25-A |

| Size | 100x25mm;length depends as per customers' request |

Technics | Wood-Plastic Composite Flooring,extrusion |

Feature | Anti-UV, waterproof |

| Component | 35% HDPE+60% wood fibers + 5% additives |

Color | Different colors available |

Decking section | Hollow |

Surface Treatment | Thin tooth |

| Quality Warranty | 15-25 years |

| Application | Swimming pool, garden, school, park, lawn,dock, playground, corridor, hotel , entertainment place, shopping center, laboratory ,living room , dance club , business hall, bathroom , massage room , etc . |

| Production Time | Within 30-45 days up receipt of your 30% deposit |

| MOQ | At least one 20' container |

| Port of Loading | Ningbo or Shanghai |

| Payment Terms | T/T,L/C at sight |

| Sample Charge | Samples free, but you need to pay the freight |

***Surface tratment of wpc decking

***Our factory and workshop & Wood-plastic composite outdoor flooring production process

Raw materials - Mixed - granulation - melt plasticizing - die extrusion - pinhole sizing and cooling

- Traction - cutting to length - Surface treatment - Qualified storage (waste crushing, recycling)