New design Co-extrusion Hollow wpc outdoor decking floor

| Min. Order: | 1000 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 20000 T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Wood-fiber Plastic Composite |

Product Detail

| Model No.: | HLHC-001 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HONOORWOOD DECK |

| Material: | wpc |

| Production Capacity: | 20000 T |

| Delivery Date: | 2 weeks |

Product Description

The HONORWOOD wpc outdoor decking:Environmental protection, start from the step!!

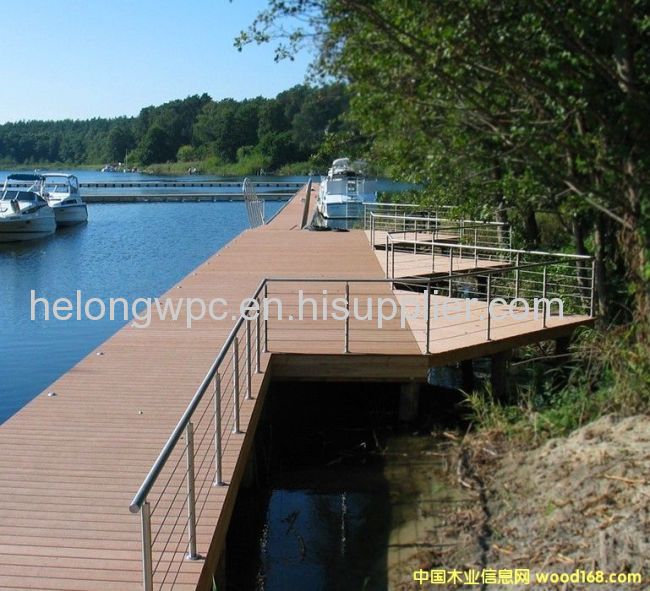

With various specification and flexible design, HONORWOOD wpc decking can meet your Different requirements freely .Let you feel walking in a beautiful outdoor environment ,enjoy the beauty of the life .

The HONOR WPC outdoor decking is made of wood-fiber,PE,Suitable for use in garden as well as public places

Featuring a matte finish for slip resistance. Each board is protected with UV inhibitors to ensure long-lastingcolor. decking ( composite decking or wpc decking ) is sturdy, durable, and versatile enough to provideyears of trouble free service. weather resistance and slip resistant surface also make it ideal for outdoor flooring and boat docks of all types.

Size:width 142mm

height 22.5mm

pore wall thickness:6mm

Edge slot wall thickness:6.5mm

Material: 70% wood fiber+20% plastic +10% additives

The co-extrusion layer is 0.7 mm thickness

Installation Guide

Installation tool: electric saw (desk type or portable),churn drill,electric portable drill and driver

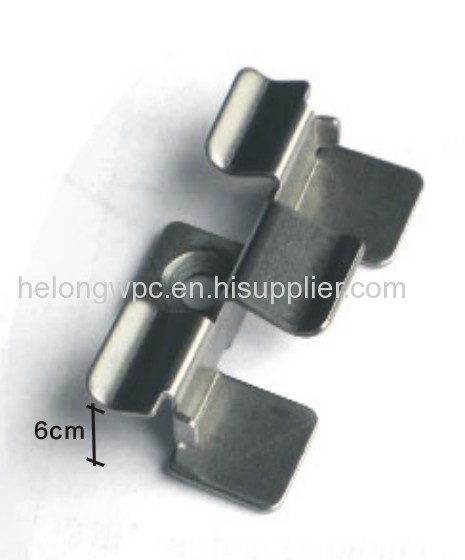

Decking and accessories:1.decking 2.joist 3.metal clip 4.the plastic expansion screws5.start clip 6.fascia

Installation step:

1.Fix the joist.

2.Decking installation.

3.Fascia installation

WPC material Advantage :

A.100% recycled ,environmentally friendly

B.Look and feel like real wood

C.anti-UV, anti-impact, anti-moisture and termites

D.service time is 10times than wood products

E.easy installation

F.suitable from -50 °C to 60°C

Product picture

Production process

1.Granulation workshop

2.Extrusion workshop

3.Post processing workshop

4.Packing