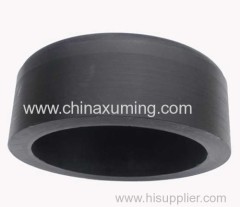

HDPE Stop Valves Pipe Fittings

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-PESV001 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Others |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Welding |

| Specifications: | DN63~DN400 |

| Color: | Black |

| Packing: | Cartons |

| Working Life: | More than 50 years |

| Export Area: | All over the world |

| Working Medium: | Water,Oil,Gas |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

HDPE Stop/Shut-off Valves Pipe Fittings

PE shut-off valve features:

Three friends stop valve PE Pipe Fittings health, non-toxic, corrosion-resistant, water and no secondary pollution; installation and connection easy.

Product pressure grade: SDR11, SDR13.6, SDR17, SDR21.

Application areas:

Polyethylene pipe industry globe valves used in urban water supply projects in rural areas, industrial and mining water projects, irrigation and livestock drinking water, garden irrigation projects.

***Workflow of HDPE Stop Valve

HDPE Stop Valve is closed parts (valve) moves along the centerline of the valve seat. According to this form of valve moves, changes in port of the valve seat and the valve stroke is directly proportional relationship. As such the valve stem to open or close the relatively short trip, but also very reliable cut-off function, and because the trip is proportional valve port and valve changes, very suitable for flow regulation. Therefore, this type of valve is suitable for cutting or regulation and throttling.

***Specification of hdpe shut-off/stop valve

| |

| Size | MOQ |

| dn20 | 1000pcs |

| dn25 | 1000pcs |

| dn32 | 1000pcs |

| dn40 | 500pcs |

| dn50 | 300pcs |

| dn63 | 200pcs |

| dn75 | 100pcs |

| dn90 | 100pcs |

| dn110 | 100pcs |

| dn160 | 100pcs |

***Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |

***Performance requirement of pipe fittings

| NO. | Item | Requirement | Test value |

| 1 | 20ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 10.0MPa PE100 12.4MPa Testing temperature: 20ºC Testing time: ≥100h |

| 2 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥165h |

| 3 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥1000h |

| 4 | Tensile strength of butt-fusion pipe fittings | Test to destruction: Flexible is good | Testing temperature:23ºC±2ºC |

| 5 | Welding strength of electro-fusion | Percentage of brittle peel: ≤33.3% | Testing temperature:23ºC±2ºC |

| 6 | Oxidation induction time | >20min | 200ºC |

| 7 | Melt flow rate | Tube melt rate of change not exceeding ±20% of the raw material | 190ºC, 5kg |

***Our workshops