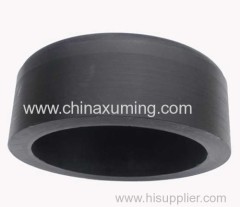

HDPE Socket Fusion End Cap Pipe Fittings

| Min. Order: | 3000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-SFC003 |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Cap |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11,SDR17 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Butt Fusion Injection |

| Specifications: | DN25x20~DN110x90 |

| Color: | Black |

| MOQ: | 3000pcs per size |

| Working Life: | More than 50 years |

| Export Area: | All over the world |

| Port of Loading: | Ningbo or Shanghai |

| Production Capacity: | 300000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

HDPE Socket Fusion End Cap Pipe Fittings

***Quality and Inspection of HDPE socket fusion end cap pipe fittings

1.Check the socket member and the socket member whether positive

2.Between the socket member from the socket member and the molten material is extruded on the outer circumference should be uniform throughout the

3.The welding area should not have impurities, shrinkage or other damage

4.Should dissolve some phenomena soldering temperature is too high or too much pressure caused appear:

If the wall collapsed, curling too large or shape is not correct and so on.

***Specifications of HDPE Socket Fusion End Cap Pipe Fittings

| |||

| Size | D(mm) | L(mm) | MOQ |

| DN20 | 26 | 22.8 | 3000PCS |

| DN25 | 32 | 25.9 | 3000PCS |

| DN32 | 41 | 30.5 | 3000PCS |

| DN40 | 51 | 34 | 3000PCS |

| DN50 | 63 | 38.5 | 3000PCS |

| DN63 | 79 | 43.5 | 3000PCS |

| DN75 | 89 | 45 | 3000PCS |

| DN90 | 105 | 50 | 3000PCS |

| DN110 | 127 | 60 | 3000PCS |

***Melt socket connection

Nominal diameter of not more than 125mm of the pipe can be melt socket connection , which is less than the nominal diameter of the pipe 63mm socket connection can be manually melt auxiliary umbra tools , the nominal pipe diameter not less than 63mm should be mechanically melt socket connection. In recent years, melt socket connected to the town water supply polyethylene pipe connections , use less and less , but in building water supply polyethylene pipe connections , use the more common. ***Melt socket connection

Hand melt socket welding generally include: heating plate and ring heater and the heating plate closely connected ; mechanical melt socket welding generally include: welding chassis , power ( hydraulic ) source , the heating plate and the ring heater . Melt socket welding main performance requirements are:

① annular heater surface temperature should be evenly coated with a release layer such as polytetrafluoroethylene , the maximum roughness (Ra) of 2.5μm;

② heating plate with circular heater should be able to closely, can effectively transfer heat ;

③ mechanical melt socket welding fittings should also be able to ensure straightness , and make the socket before connecting umbra .

Melt fusing temperature is generally socket connection 260 ± 10 ℃.

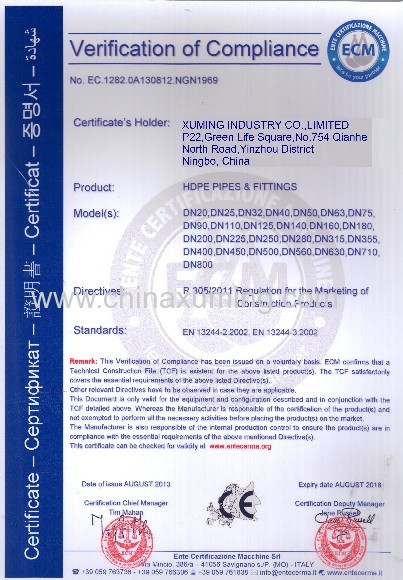

***CE certificate