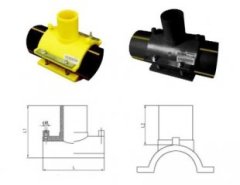

HDPE Electriofusion Straight Saddle Pipe Fittings

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-EFSS |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Others |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Welding |

| Specifications: | DN90x63~DN315x110 |

| Color: | Black |

| Packing: | Cartons |

| Working Life: | More than 50 years |

| Export Area: | All over the world |

| Working Medium: | Water,Oil,Gas |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

HDPE Electriofusion Straight Saddle Pipe Fittings

***Physical & Mechanical Properties of HDPE Material

The following table shows tha main physical,mechanical and chemical properties of polyethylene material:

| Property | Test Method | Units | PE80 | PE100 |

| Density (Compound) | ISO 1183 | Kg/m3 | 956 | 959 |

| Melt Flow Rate (190ºC/5kg) | ISO 1133 | g/10 min | 0.30 | 0.25 |

| Tensile Stress at Yield (50mm/min) | ISO527-2 | MPa | 22 | 25 |

| Elongation at Break | ISO 527-2 | % | ≥600 | ≥600 |

| Charpy Impact Strengh,notched | ISO179/1eA | kj/m2 | 14 | 16 |

| Carbon Black Content | ASTM D 1603 | % | 2-2.5 | 2-2.5 |

| Vicat Softening Point | ASTM D 1525 | ºC | 118 | 122 |

| Brittleness Temperature | ASTM D 746 | ºC | ≤-70 | ≤-70 |

| ESCR (10% lgepal),F50 | ASTM D 1693A | Hrs. | ≥10.000 | ≥10.000 |

| Thermal Conductivity | DIN 52612 | W/m°K | 0.4 | 0.4 |

| Linear Thermal Expansion | ASTM D 696 | mm/mm/k | 1.5x10-4 | 1.5x10-4 |

***Pipe SDR* And Rated Pressure Relationship

| Material | Design Sreess N/mm2 | Nominal Pressure (PN) | |||||

| 4 | 6 | 8 | 10 | 12.5 | 16 | ||

| PE100 | 8.0 | SDR41 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| PE80 | 6.3 | SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 |

| PE63 | 5.0 | SDR26 | SDR17.6 | SDR13.6 | SDR11 | SDR9 | SDR7.4 |

***HDPE Electro fusion straight saddle pipe fittings features:

1 applies to the same material of the pipe connections;

2 reliable connectivity, high seam strength, air tightness, weldability and stable;

3 injection molding, perfect structure, more secure, reliable, and inexpensive;

4 less susceptible to temperature changes and the impact of human factors;

5 welding process is simple to operate and easy to control, easy construction;

6. Investment in equipment, maintenance costs low.

***HDPE electrofusion straight saddle pipe fittings function:

Flange connections are the two pipes, fittings or pipes, the first one on each flange is fixed

between two flanges, with flange gasket, bolted together to complete the connection. Some fittings

and equipment have been built flange, also belong to the flange connection. Apply greater pressure

piping systems, with a steel flange fastened outside.

***Specifications of HDPE Electrofusion Straight Saddle Pipe Fittings

| |||||

Size ΦDxΦD1 | L(mm) | A(mm) | B(mm) | H(mm) | Φd |

| 90x63 | 145 | 155 | 80 | 145 | 4.7 |

| 110x63 | 145 | 160 | 80 | 145 | 4.7 |

| 160x63 | 190 | 230 | 100 | 185 | 4.7 |

| 160x90 | 190 | 230 | 100 | 185 | 4.7 |

| 200x63 | 190 | 235 | 110 | 185 | 4.7 |

| 200x90 | 190 | 235 | 115 | 195 | 4.7 |

| 250x63 | 190 | 300 | 115 | 195 | 4.7 |

| 250x90 | 190 | 300 | 115 | 195 | 4.7 |

| 250x110 | 190 | 300 | 115 | 195 | 4.7 |

| 315x63 | 190 | 300 | 115 | 195 | 4.7 |

| 315x90 | 190 | 300 | 120 | 200 | 4.7 |

| 315x110 | 190 | 300 | 120 | 200 | 4.7 |