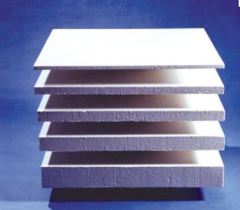

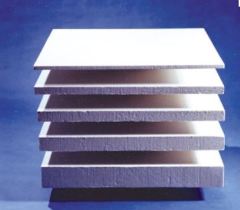

High Temperature Ceramic Insulation Board

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500 Ton/Tons per Week factory |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ceramic Insulation Board, Ceramic Fiber Yarn In White Color, Best Ceramic Fiber Blanket, Ceramic Fiber Round Rope, Best Ceramic Fiber Cloth |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Application: | Liners Of Industrial Furnace |

| Thickness: | 10-50 |

| Width: | 500 |

| Length: | 1000 |

| Grade: | HA (High Aluminum) |

| Thermal Conductivity: | 0.085-0.180(w/m.k) |

| color: | pure white |

| Production Capacity: | 500 Ton/Tons per Week factory |

| Packing: | Plastic bag inside, Carton box outside |

| Delivery Date: | 20 days after prepayment done |

Product Description

High Temperature Ceramic Insulation Board is made of bulk adding organic and inorganic binder and using wet vacuum suction filter into shape.

The product has firm texture and excellent strength,anti-erosion .

and easy cutting to process. The chemical property of refractory materials stability, so it is light and good heat insulation. It is a multi-purpose product that can be used in flame resistant of lining hot surface

and direct impact of high-temperature airflow

The product has firm texture and excellent strength,anti-erosion .

and easy cutting to process. The chemical property of refractory materials stability, so it is light and good heat insulation. It is a multi-purpose product that can be used in flame resistant of lining hot surface

and direct impact of high-temperature airflow

2. Ceramic fiber board is a type of boards made of refractory fiber materials with standard thickness. It is made of refractory fiber pulp and bond with low content of organic bond. With different refractory fiber, inorganic bond and organic bond and mixing according to different scales, we can manufacture various fiber boards and shapes which can be applicable for different temperatures (1000, 1260, 1400, 1600, 1700 and 1800). In some thermal equipments, there will be smoke generated when the bond in fiber board is burnt and the smoke will be disperses soon.

High Temperature Ceramic Insulation Board

High Temperature Ceramic Insulation Board

Application:

1. Various kinds of metallurgy steel heating furnace. Ladle-cover heat-treatment furnace, annealing oven and cap cover furnace.

2.Various kinds of ceramic kiln furnace, kiln car and kiln door in ceramic shuttle kiln, horseshoe kiln, tunnel kiln, etc.

3.Lapidification cracking furnace, converting kiln, decompressing furnace, carbonizing furnace and air fle

4. Other industrial furnaces such as soaking furnace, crucible furnace, resistance furnace and other high-temperature hot working equipment.

Technical Characteristics:

1. Low thermal conductivity

2 .Excellent thermal stability and shock resistance

3 .Excellent heat flow washing resistance and high mechanical strength

4 .Excellent elasticity. As fiber block unit keeps certain amount of compression when it is manufactured,

when building is completed, the fiber block unit expands and extrudes each other with no gap and can compensate shrinkage of fiber liner.

Accordingly insulating property of fiber furnace liner is enhanced greatly.

5 .Convenient and quick installation and excellent safety performance owing to anchoring piece is inside installed.

Physicochemical Index

Physicochemical Index | ||||||

Product | 1000 Board | 1260 Board | 1400 Board | 1600 Board | 1700 Board | 1800 Board |

Classification temperature (ºC) | 1000 | 1260 | 1425 | 1600 | 1700 | 1800 |

Bulk densityKg/m3 250-300-350-400-450-500 | 250-450 | 250-500 | 250-500 | 350-500 | 400-500 | 500 |

Linear shrinkage (%,o C x 24 hrs) | 1.3 (900) | 1.1 (1100) | 1.6 (1200) | 1.2 (1400) | 1.9 (1500) | 1.9 (1600) |

Modulus of rupture (kg / cm2) | 5 | 5 | 5 | 2 | 3 | 3 |

Chemical composition (%) | ||||||

Al2O3 | 40.1 | 44 | 52 | 58 | 72 | 80 |

SiO2 | 54.3 | 54 | 47 | 41 | 27 | 19 |

Available sizemm | 1000(L)*600(W)*6 /10/ 12.5 / 20 / 25 / 50(T) 1200(L)*1000(W)*25 / 50(T) | |||||

If anything about our above ceramic fiber board, welcome to contact: Ms. Cherry Liu Skype: Ljcherry99 Mob:0086-15132771097