Heat ceramic fiber insulation board

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ceramic Fiber Rope, Cramic Fiber Braid, Ceramic Fiber Yarn |

Product Description

| Payment & Shipping Terms | Supply Capacity | ||

|---|---|---|---|

| Payment Term: | L/C, T/T | Production Capacity: | 500 Ton/Tons per Week... |

| MOQ: | 1 Ton | Packing: | Plastic bag inside,... |

| Means of Transport: | Ocean | Delivery Date: | 20 days after... |

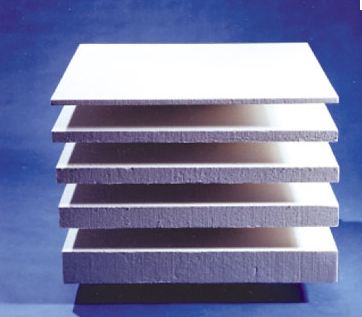

Heat ceramic fiber insulation board of 4 grades including standard, high pure, high

aluminium and zirconium adopt corresponding ceramic fiber bulk as raw material, vacuum

forming technology and dry process via drying machine guarantee our Ceramic Fiber

Board possesses delicate work. The 4 grades Ceramic Fiber Board also has close texture,

good tenacity, high intensity and anti wind-erosion nature except all the excellent

Heat ceramic fiber insulation board

Typical application:

aluminium and zirconium adopt corresponding ceramic fiber bulk as raw material, vacuum

forming technology and dry process via drying machine guarantee our Ceramic Fiber

Board possesses delicate work. The 4 grades Ceramic Fiber Board also has close texture,

good tenacity, high intensity and anti wind-erosion nature except all the excellent

Heat ceramic fiber insulation board

Typical application:

• Insulating backup to brick & castable

• Furnace hot face lining

• Use in industrial heat process equipment

• High temperature gasket & seals

• Flue & chimney linings in furnace & kilns

• Molten metal trough covers

• Expansion joint Industrial heat shields & thermal barriers

• Industrial combustion chamber construction

• Full thickness refractory lining

• High temperature boiler wall insulation

• Pouring forms for castableHeat ceramic fiber insulation board

Characteristic:

• Low thermal conductivity

• Low thermal capacity

• High thermal stability

• Resistance to thermal shock, flame and airflow attack

• High compressive strength and resistance to corrosion

• High toughness, easy to cut and install quickly

• Accurate thickness and size

• Shorter heat up and cool down time

Tech Data:

Standard | High Pure | High Aluminum | Zirconium | ||

Classifition temperature(oC) | 1260 | 1260 | 1360 | 1430 | |

Work temperature(oC) | 1050 | 1100 | 1200 | 1350 | |

Color | Pure white | Pure white | Pure white | Pure white | |

Density(kg/m3) | 280 | 280 | 280 | 280 | |

480 | 480 | 480 | 480 | ||

Permanent linear shrinkage(%) (after24hours,density320kg/m3) | -3 | -3 | -3 | -3 | |

(1000oC) | (1100oC) | (1200oC) | (1350oC) | ||

Thermal conductivity(w/m.k) density285kg/m3) | 0.085(400oC) | 0.085(400oC) | 0.085(400oC) | 0.085(400oC) | |

0.132(800oC) | 0.132(800oC) | 0.132(800oC) | 0.132(800oC) | ||

0.180(1000oC) | 0.180(1000oC) | 0.180(1000oC) | 0.180(1000oC) | ||

Compressive strength (Mpa) (thermal shrinkage 10%) | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical composition (%) | AL2O3 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 97 | 99 | 99 | - | |

AL2O3+SIO2+Zro2 | - | - | - | 99 | |

Zro2 | - | - | - | 15-17 | |

Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size (mm) | 1200x1000; 1200x600; 1000X1000, 900x600; 600x300 | ||||

Thickness | 6-80mm | ||||

Heat ceramic fiber insulation board has been presented above, want more similar products, please click ceramic fiber insulation board.

Our Heat ceramic fiber insulation board is good in quality and competitive in price. We manufacture Heat ceramic fiber insulation board and supply OEM, ODM service according to your requirement.

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Our Heat ceramic fiber insulation board is good in quality and competitive in price. We manufacture Heat ceramic fiber insulation board and supply OEM, ODM service according to your requirement.

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

.gif)