Toilet paper making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Reeling Machines, Pulpers, Pulping Equipments, Paper Complete Equipment, Paper Cutting Machines |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Product Type: | Others |

| Certification: | CE |

| Processing Type: | Winding Machine |

| Brand Name: | Fubei |

| Type: | paper machine |

| Packing: | wood packing |

Product Description

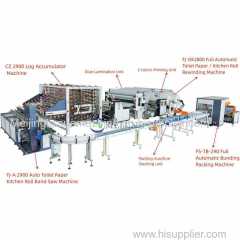

Rewinding and Perforating Toilet Paper Making Machine

1 CE

2 Can design the machine specially for you

3 Provide some spare parts freely

1 CE

2 Can design the machine specially for you

3 Provide some spare parts freely

Toilet paper making machine

Technical Parameter:

Technical Parameter:

Product: Toilet Paper, face tissue,napkin etc.

Grammage: 15-30g/m²

Breadth: 787-3000mm

Speed of the machine: 60-500m/min

Driving mode: AC drive, frequency control of motor speed, sectional drive

Equipment Function & Character:

Equipment Function & Character:

1.This machine adopts advanced servo driving system, PLC program controlling technical and touching screener operation table. This machine can materialize continued splicing the craft-paper core under high speed production without stopping the machine; It possesses stable production, high production output, simple operation, easy maintaining and small noise;

2.Under European CE standard designing, Passed CE certificate, With CE or UL certificate for Electric Parts and with safety device, such as, safety-guard door, emergency stop and so on.

3.Most of parts are precisely processed by numerical-control machine; the key mechanical parts are under CNC processing; while the main outsourcing parts are world famous brand.

4.Kitchen towel embossing and laminating system: When producing kitchen towel, through this system, it makes embossment on jumbo roll and glue lamination on the protruding surface to enable two ply of jumbo roll sticking together into one, because glue laminating only on the protruding surface of paper can preserve some air for the non-embossed area between two ply of toilet tissue, thus to increase the absorption of final products.

5.Automatic roll core splicing unit without manual core feeding; Auto edge trimming, glue spraying and sealing synchronously in one time, which had materialized the technique of popular edge-trimming and tail-gluing as well as auto pushing out the final products after rewinding;

6.Monitoring system on broken paper or ripping edge under high-speed running the equipment; Jumbo roll tension controlling system; Air pneumatic lifting the jumbo roll