PVC decorative sheet making machine

1.0~160000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-FPB80 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | JBD |

| Power: | 75kw |

| Capacity: | 300-400kg/h |

| Screw design: | twin screw |

| Screw diameter: | 80mm |

| Main motor power: | 75kw |

| Capacity: | 300-400kg/h |

| Heating power: | 36kw |

| L/D: | 22:1 |

| Applicable material: | PVC resin |

| Board width: | 1200-1500mm |

| Board thickness: | 2-10mm |

| Material of screw and barrel: | 38CrMoAlA |

| Production Capacity: | 50 sets per year |

| Packing: | EPE film or wooden cases |

| Delivery Date: | 50 working days |

Product Description

1. Main equipment of production line

(1) Twin conical screw extruder foam board special extruder

(2) Plate of auxiliary

(2) Plate of auxiliary

Include a.Vertical three-roller calendaringmachine

b.Cooling units

c.Traction trimming machine

d.Cutting machine

(3)Foam plate mold (to produce 2-18mm thick)

Contains three sets of die lip

(4) Supporting auxiliary engine production line

c.Traction trimming machine

d.Cutting machine

(3)Foam plate mold (to produce 2-18mm thick)

Contains three sets of die lip

(4) Supporting auxiliary engine production line

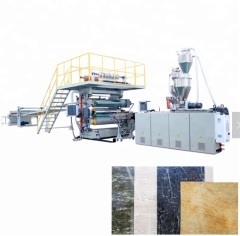

2.The application of PVC Decorative Sheet

Transportation:such as steamship,aeroplane,carriage,train compartment, roof shed, case core layer, inner upholster,etc.

Architecture:such as building wall board,decoration board,housing, office, public building interlayer, commercial decoration shelf,non-dust room board,ceiling plate,etc.

Advertisement:such as screen printing, computer lettering,ad board,etc.

Equipment lists:

1 | SJSZ-80/156 Twin screw extruder |

2 | Automatic feeding system |

3 | Mold |

4 | Three rollers calender machine |

5 | Precool unit |

6 | Roller temperature controller |

7 | Cooling support stacker, and edge cutting unit |

8 | Haul off unit |

9 | Cutting unit |

10 | Stacker |