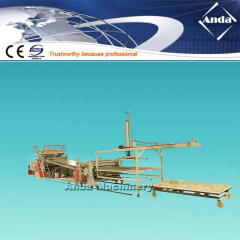

PVC Marble Sheet Making Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 0-150sets per year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | kpm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| board wide: | 1220mm |

| thickness: | 1-8mm usually |

| extruder: | SJZ80/156 |

| main extruder: | 75KW |

| output:: | 350KG |

| motor: | SIEMENS motor |

| inverter: | ABB |

| installation size: | 22X4X3.5M |

| color: | according to you idae |

| certificate: | ISO9001 CE |

| Production Capacity: | 0-150sets per year |

| Packing: | suitable sea transport package |

| Delivery Date: | 45 working days after deposit money received |

Product Description

PVC Imitational Marble Sheet/Board/Profile Making Machine

PVC plastic stone board extrusion line

PVC Imitation marble board production line

PVC artificailal marble board made of PVC material + Ca2Co3, has advantage of water-proof, anti-corrosion, easy cleaning, easy setting up, colorful, hard surface etc.

The product has marble pattern, granite pattern, imitation wood grain, rationale pattern, solid color semipermeable heart and other patterns.

PVC imitation marble board production line processing:

Crusher (crushing the edge of board trimmed) → Miller (milling the scraps into powder) → Mixer (mixing the main materials and additives) → SJSZ 80/156 conical double Screws Extruder → Mould → Lamination unit → Three-calender unit → Cooling Bracket → Hual-off Machine → Edge Cutting → Cutter → Stacker → UV coating machine(choose need or not)

Machinery part:

1. SRL-Z500/1000 hot-cooling mixer, capacity 500-700KG/H, driven by 75KW XIMO motor adjust by ABB inverter.

capacity 500-700KG/H, driven by 75KW XIMO motor adjust by ABB inverter.

self friction & electric heating for hot mixer, water cooling for cooling mixer.

tank wall made by 8mm thickness stainless steel.

2. conical double screw extruder with screw loader Benk's conical double screw extruder equiped with parallel twin screw feeder, which can avoid the PVC powder material block.

Benk's conical double screw extruder equiped with parallel twin screw feeder, which can avoid the PVC powder material block.

Screw feeder equiped with limit switch, which used to guarantee the material loading equal and continously. or equip with vacuum loader, which can help solve PVC powder dust problem for client.

3. extrusion and forming mould

4.three roller

5, cutter

Main technical parameters:

| Main extruder and motr | SJZ80/156 conical double screw extruder 75kw |

| Co-extruder and motor | SJZ65/132 conical doule screw extruder 37kw |

| cooling roller | stainless steel |

| haul-off | 8 roller haul-off 5.5kw |

| cutter | 2.2kw feeding motor 1.5kw |

| output | 450kg/h |

Auxiliary machinery

| wood powder making machinery | 150-300kg/h |

| SRL-Z500/1000 mixer | 500-700kg/h |

| PC500 crusher | 300kg/h |

| SMF-500 miller | 250-300kg/h |