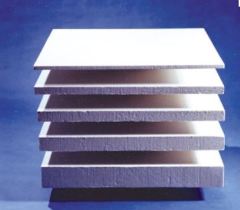

ceramic fiber blanket for heat insulation

650.0~750.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 tons/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Zibo, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | YUN TAI |

| size: | 7200*610*10-50mm |

| Production Capacity: | 200 tons/month |

| Packing: | carton |

| Delivery Date: | 20days |

Product Description

ALUMINUM SILICATE SWINGING FIBER BLANKETS

1.TEMPERATURE CLASSIFICATION

COM alumina silicate swinging fiber blankets 1100 ℃

ST alumina silicate swinging fiber blankets 1260℃

HP alumina silicate swinging fiber blankets 1260℃

HA alumina silicate swinging fiber blankets 1360℃

HAZ alumina silicate swinging fiber blankets 1360℃

HZ alumina silicate swinging fiber blankets 1430℃

2.OPERATING TEMPERATURE

Operating temperature is determined by using conditions, heating manners and environment atmosphere, etc.

3.PRODUCTION ENGEERING

The swinging fiber blankets have long fibers with even diameters and low sediment balls with improved functions in fiber interweaving, resisting layers divided resisting wind erosion, pliability and tensile strength, thus have improved the applied function and reduced the loss of materials. The swinging blandest does not use any binding preparation to make sure that the products possess perfect liability and stability under all kinds of environment.

4. TECHNICAL FEATURE:

Low thermal conductivity and low heat storage

Excellent thermal stability and thermal vibration resistance

Excellent erosion resistance

Excellent heat insulation, fire proofing and processing function

5. APPLICATION:

Industrial furnace, heaters, inside wall of high temperature tube.

Electric power furnace, nuclear power station and heat insulation.

Liners of chemical industry high temperature reaction equipment and heat insulation.

Fire proofing and heat insulation of high building.

Heat insulation for kiln door and lid.

Filtration material of high temperature.

Item | COM | ST | HP | HA | HAZ | HZ | |

Classification Temperature℃ | 1100 | 1260 | 1260 | 1360 | 1360 | 1430 | |

Working Temperature ℃ | <1000 | 1050 | 1100 | 1200 | 1200 | 1350 | |

Density kg/m3 | 96 128 | 96 128 | 96 128 | 128 160 | 128 160 | 128 160 | |

Permanent linear shrinkage (%) (holding temperature for 24h, density128kg/m3) | -4(1000℃) | -3(1000℃) | -3(1100℃) | -3(1250℃) | -3(1250℃) | -3(1350℃) | |

Thermal conductivity (w/m.k) density 128kg/m3) | 0.09(400℃) 0.176(800℃) | 0.09(400℃) 0.176(800℃) | 0.09(400℃) 0.176(800℃) 0.22(1000℃) | 0.132(600℃) 0.22(1000℃) | 0.132(600℃) 0.22(1000℃) | 0.176(600℃) 0.22(1000℃) | |

Tensile strength (Mpa) density128kg/m3) | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | |

Chemical Composition (%) | AL2O3 | 42-44 | 45-46 | 47-49 | 52-55 | 45-46 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | --- | --- | |

AL2O3+SIO2+ZrO2 | --- | --- | --- | --- | 99 | 99 | |

ZrO2 | --- | --- | --- | --- | 5-7 | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | 0.2 | |

Size(mm) | Common 7200X610X10-50;7200x1220x10-50 Other made according to customer's requirement | ||||||