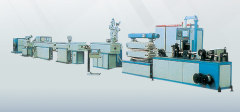

Plastic extrusion machine for pe pipe

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | SJ75 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Waste Plastic Crusher |

| Shaft Design: | Single |

| Brand Name: | BENICE |

| Power: | 55KW |

| Capacity: | 280KG/H |

| PROCESSING TYPE: | PE PIPE EXTRUDER LINE |

| MATEIAL: | LDPE,HDPE,HDPE |

| STANDARD: | PE63,PE80,PE100 |

| PIPE DIAMETER: | 75-110MM |

| Production Capacity: | 10sets/month |

| Packing: | packing in film |

| Delivery Date: | 30working days after down payment |

Product Description

PE pipe plastic extrusion machine production specification

PE pipe plastic extrusion machine inlude single screw extruder, pe pipe mould, calibration and water spraying tank, haul-off machine, stacker.

1.Special single screw extruder for polyolefin, having high extruding speed

and effective plasticization.

Separation mixing screw specialized for

polyolefin.

Specially designed three co-extruding die, reasonable

channel, smooth outside and inside wall,and little internal stress.

2.Producing pipe limit 16-1200mm(pipe diameter according to your exact requires), manufacture velocity up to 16m/min. May be used to produce

HDPE silicon core tube, ordinary PP-R, PEand PEX pipes.

3.Low cost:

The cost of nanometer & anti-virus pipe is merely increase 5-10% on the

ordinary pipe basis.

PE pipe plastic extrusion machine High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialized screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket die head, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely. If you have any needs about PE pipe extrusion line feel free to contact me. Skype is benicexiaofei

PE pipe production line main technical parameters:

| Benice Company PE Pipe Production Line Main Technical Parameters(JUST FOR REFERANCE) | ||||

MODEL | OD RANGE (mm) | MATCHED EXTRUDERS | OUTPUT(kg/h) | TOTAL INSTALLED POWER(kw) |

| HDPE-63 | 20-63 | SJ60/33 SJ25/25 | 120-220 | 90 |

HDPE-160 | 75-160 | SJ75/33 SJ25/25 | 120-220 | 120 |

HDPE-250 | 160-250 | SJ75/33 SJ25/25 | 280-350 | 280 |

| HDPE-450 | 250-450 | SJ90/33 SJ25/25 | 350-450 | 400 |

HDPE-630 | 315-630 | SJ120/33 SJ25/25 | 550-850 | 550 |

HDPE-800 | 450-800 | SJ150/33 J25/25 | 800-1300 | 750 |

| HDPE-1000 | 600-1000 | SJ150/33 SJ25/25 | 800-1300 | 750 |

| HDPE-1200 | 800-1200 | SJ150/33 SJ25/25 | 800-1300 | 900 |

PE PIPE PRODUCTION LINE SPARE PARTS:

SINGLE SCREW EXTRUDER WITH AUTOMATIC FEEDER SYSTEM:

SJ25/25 PE PIPE MAKR LINE EXTRUDER:

HDPE PIPE DURABLE MOULDS

Keywords: PE pipe production line, PE pipe extrusion line, PE pipe extruding line, PE pipe production machine, PE pipe extrusion machine, PE pipe extruding machine, PE pipe machine, PE pipe processing machine, PE pipe making machine, PE pipe production machine line.