Co-extrusion Snack Processing Machine

6000.0~30000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30set/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Co-extrusion Snack Making Machine, Kurkure Machine, Coextrusion Snack Machine, Cheese Curl Machine, Double Screw Food Extruder |

Product Detail

| Model No.: | DS series |

|---|---|

| Means of Transport: | Ocean |

| Processing Types: | Snack |

| Processing: | Frying Machine |

| Brand Name: | saixin machinery |

| Co-extrusion Snack Processing Machine: | Co-extrusion Snack Machine |

| Co-extrusion Snack making Machine: | Co-extrusion Snack Processing line |

| Coextrusion Snack making Machine: | Coextrusion food making Machine |

| Production Capacity: | 30set/month |

| Packing: | wooden case |

| Delivery Date: | 20days |

Product Description

Co-extrusion Snack Processing Machine

Coextrusion system

This co-extrusion technology is a response to market pressures that

requires a steady stream of convenient, tasty and attention-grabbing new

products to stimulate interest and satisfy consumer expectations.

Coextrusion system

This co-extrusion technology is a response to market pressures that

requires a steady stream of convenient, tasty and attention-grabbing new

products to stimulate interest and satisfy consumer expectations.

Co-extrusion systems provide a capability to make added-value products

with out of the ordinary shapes that catch the eye, complemented by exotic

flavours and fillings. The fillings can be of virtually any colour or

flavour - sweet or savoury creams, fruit pastes or chocolate pralines are

typical. Even more appeal can be added with glazings, frostings or

coatings such as chocolate.

with out of the ordinary shapes that catch the eye, complemented by exotic

flavours and fillings. The fillings can be of virtually any colour or

flavour - sweet or savoury creams, fruit pastes or chocolate pralines are

typical. Even more appeal can be added with glazings, frostings or

coatings such as chocolate.

They also provide the means of incorporating fillings with contrasting

textures or colours into a cereal outer. The essential elements are a die,

pillow crimper and cream feed system.Co-extruded cereal products can be

positioned as pet or infant foods as well as mainstream snack or cereal

products.

textures or colours into a cereal outer. The essential elements are a die,

pillow crimper and cream feed system.Co-extruded cereal products can be

positioned as pet or infant foods as well as mainstream snack or cereal

products.

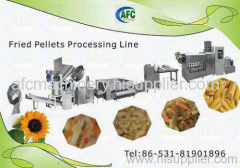

Co-extruded snacks production line

Co-extrusion system (Double Screw Extruder plant working with

Center-filling Machine) provides the means of incorporating fillings with

contrasting textures and colours into a snack outer. Fillings can be of

virtually any colour or flavour – sweet and savoury creams, fruit pastes,

cheese and chocolate are typical. Co-extruded products can be made in

virtually any length from 12 to 120mm by Pillow Cutter machine or Bar

Cutter machine, so filled bars can be marketed as individually wrapped

count lines.