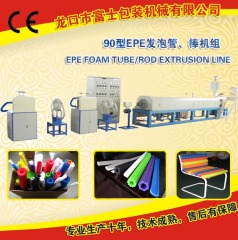

Advanced Processing PE Foam Tube Extrusion Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50set/year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

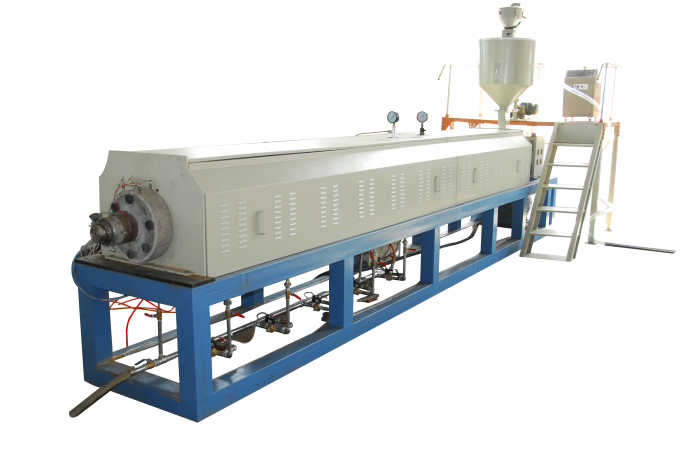

| Model No.: | FS-FPG105 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | FS |

| Power: | 120KW |

| Processing Type: | Foaming Machine |

| Product Type: | Foam Pipe |

| After-sales Service Provided: | Engineer available to service oversea |

| Dimension(L*W*H): | 25x3x3m |

| Cooling method: | Water |

| Product Specifications(mm): | φ20-100 |

| Screw Speed(r/min): | 5-40 |

| Weight: | 9 |

| Certification: | CE |

| Warranty: | 1 year |

| Production Capacity: | 50set/year |

| Packing: | Export standard packing |

| Delivery Date: | About 25-30days |

Product Description

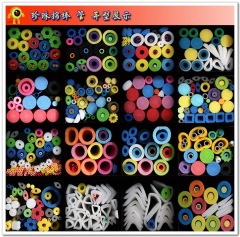

Believable Polyethylene Plastic Foam Tube Extrusion Line

Applications

EPE foam pipe is a kind of new-type foaming material and it is widely used in the installations of air conditioner pipeline, heat insulation,

toy guardrail, recreation places etc. due to its good foaming, elasticity and heat preservation.

Features

1. Fully Automatic Working

2. Synchronized Work

3. Speed Control by Inverter

Specifications

Items | Unit | Magnitude |

diameter of Screw | mm | 105 |

Dispsoal Material | LDPE | |

Diameter of Product | mm | 30-100(Tube) 10-60(Rod) |

Output | kg/h | 80-120 |

Rated Output | KW | 120 |

External Dimension | mm | 25000×3000×3000 |

Weight | T | About 9 |

Machine Detailes

A.Loading Part

1.Automatic Adding Charge

Disposal Material | Nucleating agent |

Feeding Capacity | 2-30g/min |

Driving Motor | 0.75kw |

2.Vacuum Vutomatic Feeder

Capability of Conveying Feed | 300kg/h |

Specification of Motor | 0.75KW |

Elivery Lift | 4.5m |

B.Extruder

Screw Bolt and Barrel Material | 38CrMoAlA nitrogen treatment |

Main Motor Style | Structure profile of three-phase asynchronous motors |

Reducer | Special reducer with rigid tooth surface, large twisting moment, high rev and low noise |

Heater | Cast aluminum heater, adopt the solid-state relay, no contact to output, intelligent temperature controller control the temperature. |

Cooling Type | Water cycling cool, automatic by-pass system |

Diameter of Screw(mm) | φ105 |

L/D Ratio of Screw | 55:1 |

Max rev of Screw(rpm) | 60 |

Max. Amount per Day(kg/h) | 120 |

Stages of Heating | 10 |

C.Extruder Die

Structure | Extruder die is round, die orifice depend on specification to change |

Material | Chrome-steel-made: flow channel roughness Ra0.025μm |

Diameter of Die Orifice | Depend on diameter of product |

Zones of Temperature Control | 1 |

Precision of Temperature Control(℃) | ±1 |

Heating Power(KW) | 5 |

D.Former Injection Unit

Sort of Pump | high pressure measure pump |

Flow of Metering Pump(L/H) | 63 |

Output Pressure(MPa) | 10-20 |

Pressure Panel(MPa) | 0-60 |

Motor Power(KW) | 2.2kw |

E.anti-contractor Injection Unit

Sort of Pump | high pressure measure pump ,double pillar piston |

Sort of Anti-Shrinkage Agent | Static acid monoglycerides |

Flow of Pump(L/H) | 10 |

Volume of Melting Pot (L) | 10 |

Pressure Panel(MPa) | 0-60 |

Motor Power(kw) | 0.75 |

F.Cooling Calibration and Conveying System Unit

Cooling Type | Wind cooling by air ring |

Conveying Type | second press roller convey. |

Specifications of Press Roll | make of steel,embossing,hard chromium on the surface |

Conveying Control | Structure profile of three-phase asynchronous motors, Frequency control timing. |

Blower Power | 120w×3 |

Amount of Press Roller | 2 |

Puller Power | 0.75kw×2 |

G.Cutting Transmission Unit

Cutting Type | Mechanical cutting |

Cutting Control | Meter-counting and transducer control the processing, voltage regulator control current. |

Length of Cutting | length can adjust |

Driving Power | 0.75kw |

Final Production

Packing And Shipping

Our Customers All Over The Word

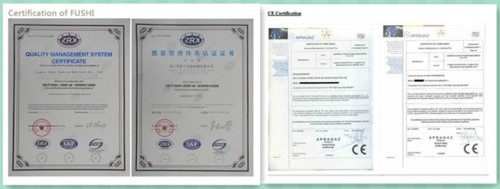

Our Certification

COMPANY INFORMATION

Longkou Fushi Packing Machinery Co., Ltd

Founded in 1994,Longkou Fushi Packing Machinery Co., Ltd has developed CE certified Plastic Extrusion Machinery, Vacuum Forming Machine, Fruits Cleaning,

Waxing&Grading Machine, PS/EPE foam Sheet Extrusion Line, EPE foam Net Extrusion Line, XPS Foam Board Extrusion Line, PE Cap Liner Foam Sheet Extrusion Line,

PE/PS Recycling and Pelletizing Line, totally more than 20 kinds of machines, which are widely used in the fields of fruits making&processing, furniture packing,

food, medical apparatus&pharmaceutical, electron, arts&crafts, construction industries, etc.

We are one of the leading manufacturers of packing materials and related machinery. During sixteen years of development, we are highly experienced in

machinery manufacturing. With the market share expanding quickly year after year, the sales of our products are progressively increasing. The performance of

our machinery is always on the leading place compared with the same products in the market depending on quality and price.

Depending on high products quality and excellent after-sales service, our company enjoys great reputation among our customers. The products are selling well

in more than 20 provinces in China, and also exported to several countries and districts. Our excellent after-sales service could always guarantee regular technical

support to our customers.

We are pleased to welcome domestic and overseas friends to visit us and cooperate with us.

FAQ

1: Why I choose your company?

1) We are China Leading machine Manufacturer.

2) Our company have mademachine about 30 years with strong experience and advanced technology.

3) Best Quality &Service with Reasonable price.

4)100% inspection Before Shipment.Quality is priority. we always attach great importance to quality

controlling from the very beginning to the very end.Our factory has gained government authentication.

2:What should you prepare except material?

You should prepare factory, water, electric, and we are very glad to help you purchase procuct if you need. And we can design

the workshop layout for you if you need.

3: If we can customize a suitable machine for yourself?

Of course, we can making equipment accordig to your requirement.Such as, electric brand, capacity, scutcheon, mould style ect.

4: Where is your factory located? How can I visit there?

Our factory is located in Longkou City, Shandong Province in China. Warmly welcome to visit us!