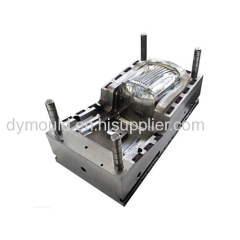

chair plastic injection mould

30000.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Agent, Service |

| Main Products: | Plastic Mold Mould Injection, Plastic Injection Molding Machine, Injection Moulding Machine PET, Pet Perform Mould, Perform Mould |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Product: | Household Appliance |

| Product Material: | Steel |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | Mitstrong |

| Production Capacity: | 200 |

| Packing: | wooden cases |

| Delivery Date: | 50~70 |

Product Description

We are one of best plastic chair mould company in China,have rich experience in makingplastic chair mould,such as arm chair mould,baby chair mould,beach chair mould.Annually nanufacturing over then 10 sets of plastic chair moulds.we know how to make good quality mould with good price.

It's very important have good plastic chair mould design,reasonable mould structure,cooling system,guide system,air ventingsystem.Normally we will send 3d drawing to our customerconfirmed,to make sure mould drawing will have no problem.

Choosing the suitable steel,we think DIN1.2738 is a very good for chair mould,but consider with steel cost,customer usually will choose P20.

Using best suitable tooling technical,need 3 stages finisheing by CNC mcahine,rough milling,precise milling,final precise milling.

Good polish,need make the parting line finishing good and without any shap edges,otherwise,it's dangerous.

Here is plastic chair mould details we have made,only for reference:

Housing 1.1730Cavity/Core 1.2738 HRc 30-32c

In this article,we will tell you how to distinguish whether the chair mould is good or not.

Tips of choosing chair mould China:

1.Cycle time of chair mould

2.Life of chair mould

3.Parting line of chair mould and whether there is a sharp edges

4.Whether the chair mould has even wall thickness

5.Whether the chair has good stacking

6.Venting design of the back of chair

7.The permanence of chair mould polishing

8.Whether the chair with light weight and intensity