Taizhou manufacturing high quality plastic injection chair mould

500.0~10000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 sets /month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Mould, Injection Mould |

Product Detail

| Model No.: | KJ009 |

|---|---|

| Means of Transport: | Ocean, Air |

| Product: | Household Product |

| Product Material: | Steel |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | KJ MOULD |

| Item: | plastic injection chair mould |

| Cavity: | single |

| Runner: | Cold / hot |

| Mould Steel: | P20, 718,2316,2738,S136,H13,etc. |

| Mould Base: | LKM,HASCO,etc. |

| Design Software: | UG,PROE,CAD,etc. |

| Processing Tolerance: | 0.003-0.005 |

| Equipment: | CNC,EDM,etc. |

| Delivery Time: | 30-60 days |

| MOQ: | 1 set |

| Production Capacity: | 30 sets /month |

| Packing: | In wooden case |

| Delivery Date: | 30-60 days |

Product Description

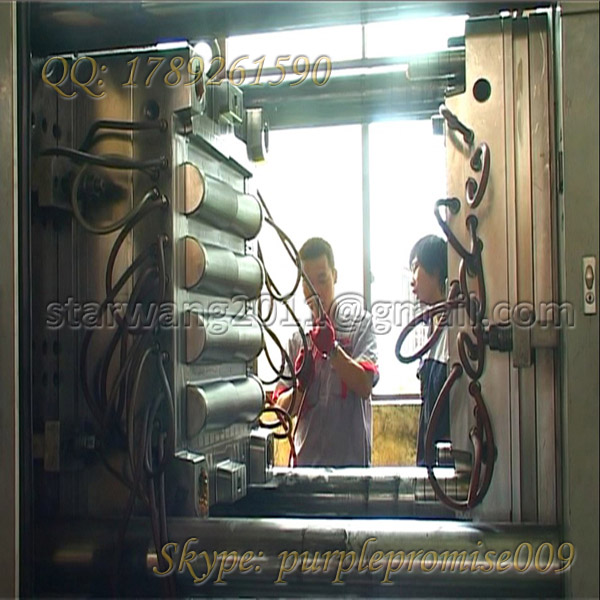

1.The series of plastic injection chair mould we have made

2.Detailed description of plastic injection chair mould:

3.plastic injection chair mould making process

4. plastic injection chair mould quality control

5.plastic injection chair mould pack and shipping

6. plastic injection chair mould maintenance

8.Contact Information

2.Detailed description of plastic injection chair mould:

name | plastic injection chair mould |

mould material | 45# 50# 718 2738 P20 S136 etc |

mould design | 3D/2D |

design days | 3-5 days |

mould life | 300.000-3.000.000 |

plastic material | PE PC PS PP ABS PVC etc. |

injection system | pin-point gate |

payment | 40% of deposit by L/C T/T 60% of balance by L/C T/T |

3.plastic injection chair mould making process

Processing | Time |

Prepare Steel | 5 days |

CNC Machining | 10 days |

Drill | 8 days |

Heat treatment | 6 days |

High speed CNC Machining | 7 days |

Assembling and Fitting | 6 days |

Polishing | 6 days |

T1 mould test | 2 days |

Total: It is 50 days for first mould testing after mold design is confirmed.

4. plastic injection chair mould quality control

For the Q/C of mold, there are 3 steps:

1.Mold Material Q/C

- Mold Steel Checking(Hardness, flaw detection)

- Mold Standard Spare Parts Checking(hardness, size, flaw checking)

2.Mold Making Process Q/C

- design checking (part design, mold design, mold engineering drawing)

- Each part of mold's size checking after machining according to 2D drawing

- mold testing(check mold running condition)

3.check with customer's requirement again before mold shipping.

5.plastic injection chair mould pack and shipping

Anti-rust oil is painted first, then Plastic film, and finally Wooden Case.

Sent together with the mold:

a) Mold manual instruction

b) engineering drawing in flash disk

c)one more set of mold spare parts:heater,ejector pin,bush,water nozzle,water pipe,hanging ring.

6. plastic injection chair mould maintenance

a)When the mold is vacant, spray the anti-rust oil

b)To clean the gate and cooling system regularly

c)Avoid to use recycled material if the mold is suitable for virgin material only

a)Engineering and one interpreter can be sent to customer's factory for first running.

b)one-year after-sale technique support

8.Contact Information

Mobile: 86-182 5765 6437

Email: starwang2011 (at) gmail(.) com

Skype: purplepromise009

QQ: 1789261590

Skype: purplepromise009

QQ: 1789261590