Energy-saving Circulating Fluidized Bed Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | DHX series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | coal-fired or biomass fuel |

| Output: | rated heat output:7-116MW |

| Usage: | heating company |

| Structure: | water tube |

| Pressure: | low pressure |

| Style: | vertical |

| Type: | forced circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard exporting package |

| Delivery Date: | 6 month |

Product Description

Energy-saving Circulating Fluidized Bed Boiler takes the principle of stationary design and circulating fluidized bed map as the guide,the theory of material balance and the theory of particle fuel combusition and a more substantial reduction in the total bed stock,thus form the flow pattern based on the re-structure of Energy-saving Circulating Fluidized Bed Boiler technology.It represents the latest developments direction of the circulating fluidized bed technology.The structure features of Energy-saving Circulating Fluidized Bed Boiler is :

1 The structure of a single drum Energy-saving Circulating Fluidized Bed Boiler transverse type

2 The suspension furnace of energy-saving circulating fluidized bed boiler equipped with film water-cooled wall and the imports of separator is water-cooled flue

3 The use of bell hood of Energy-saving Circulating Fluidized Bed Boiler that 's easy to replace,low resistance,non-inverted gray

4 The separator and the center tube of energy-saving circulating fluidized bed boilerhave the technological improvements for low resisitance,high separation efficiency

5 The use of patented technology and equipped with independent device of roots blower to save power consumption

6 The use of low bed pressure operation.

7 The use of lower pressure fans,reducing the power consumption of fans

8 Optimization of secondary air layout and flow vents to reduce the secondary air pressure of fans

9 To improve the fuel crusher and screening system,the coal particalsize is in line with design requirements

10 The air preheater use of a multi-tube boxarrangement,and low-temperature use of corrosion-resistant steel to avoid the corrosion due to low temperature cause to replace the whole.

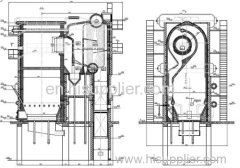

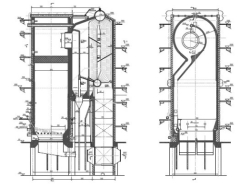

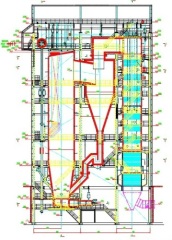

·The diagram of energy-saving circulating fluidized bed hot water boiler series1 The structure of a single drum Energy-saving Circulating Fluidized Bed Boiler transverse type

2 The suspension furnace of energy-saving circulating fluidized bed boiler equipped with film water-cooled wall and the imports of separator is water-cooled flue

3 The use of bell hood of Energy-saving Circulating Fluidized Bed Boiler that 's easy to replace,low resistance,non-inverted gray

4 The separator and the center tube of energy-saving circulating fluidized bed boilerhave the technological improvements for low resisitance,high separation efficiency

5 The use of patented technology and equipped with independent device of roots blower to save power consumption

6 The use of low bed pressure operation.

7 The use of lower pressure fans,reducing the power consumption of fans

8 Optimization of secondary air layout and flow vents to reduce the secondary air pressure of fans

9 To improve the fuel crusher and screening system,the coal particalsize is in line with design requirements

10 The air preheater use of a multi-tube boxarrangement,and low-temperature use of corrosion-resistant steel to avoid the corrosion due to low temperature cause to replace the whole.