QXX Series 14MW Circulating Fluidized Bed Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | QXX Series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | coal, lignite |

| Output: | 14MW |

| Usage: | industry |

| Structure: | water tube |

| Pressure: | low pressure |

| Style: | a vertical type with double drum |

| Type: | forced circulation |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | four months |

Product Description

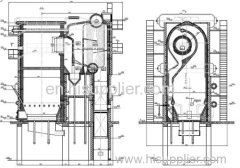

QXX Series 14MW Circulating Fluidized Bed Boiler is forced circulating fluidized bed hot water boiler.Convection heating surface adopts convection tube between the upper and lower drum form, except economizer.so that the boiler has a large water capacity.Whena sudden power outage ,it can play a buffer role in enhancing their ability to protect the boiler.

·National patent

QXX Series 14MW Circulating Fluidized Bed Boiler has the characteristic:combustion efficiency and boiler thermal efficiency is very high. Conducive to ash utilization.improving economic efficiency.

QXX Series 14MW Circulating Fluidized Bed Boiler adopts double drums.Fuel is into the furnance by coal feeder.It burns with air from isobaric bellows.The gas from burnning goes up into horizontal cyclone. Cyclone is composed by three membrane wall so as to keep the cyclone operation stable.The ash from gas is seperated by inertia.It is sent into furnace by loose wind through back forehearth.Then it circulating burns. It improvs the burnning efficiency.The seperated gas go out from cyclone.It from up to down through U flue bend ,further separate the particals from flue gas,scour convection tube bundle.Then goes into steel economizer.The economizer is two layout.Flue gas scour the economizer into air preheater,then into the chimmey by ID fan through dust collector. Boiler ventilation mode isthe balanced ventilation of blower and fan.

Layout and select measuring points must be met with TSG G0002-2010(Appendix B:Boiler Instrument Configuration Requirements).Boiler must be install the interlocking devices.When all induced draft fan power outage,it can automatically cut off the air and fuel supply.When all forced draft fan power outage,it can automatically cut off the fuel supply.

Basic characteristics of QXX Series 14MW Circulating Fluidized Bed Boiler

1.boiler specification

rated thermal power 14MW

rated outlet water temperature 115℃

rated water pressure 1.25MPa

rated inlet water temperature 70℃

exhaust gas temperature 150℃

hot air temperature 320℃

thermal efficiency 84.6%

2. Design fuel is lignite. low calorific value of fuel is no less than 12332KJ/Kg. fuel particle diameter is of 0 ~ 10mm, particles of less than 1mm is not exceed 30%.

QXX Series 14MW Circulating Fluidized Bed Boiler thermal characteristics

Index | Parameter |

fluidized bed outlet temperature | 928℃ |

Burning room outlet flue temperature | 913℃ |

convection tube bundle outlet flue temperature | 300℃ |

economizer outlet flue temperature | 195℃ |

economizer out watertemperature | 73℃ |

fuel consumption | 4451.8Kg/h |

boiler design thermal efficiency | 84.6% |

circulating water rate | 266t/h |

boiler proper water volume | 16.5t |

QXX Series 14MW Circulating Fluidized Bed Boiler power consumption

item | power |

forced draft fan | 132kw |

induced draft fan | 132kw |

added water pump | 11kw |

coal feeder | 0.75kw |

·National patent