64MW Circulating Fluidized Bed Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Fuel: | coal, lignite, slag |

| Output: | 64MW |

| Usage: | industry |

| Structure: | water tube |

| Pressure: | low pressure |

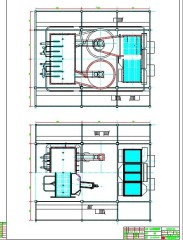

| Style: | a verticaltype with double drums |

| Type: | forced circulation |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | six months |

Product Description

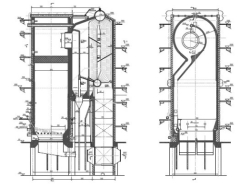

64MW Circulating Fluidized Bed Boilers

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

64MW Circulating Fluidized Bed Boilers are circulating fluidized bed hot water boiler. It isforced circulation, safe and reliable.

Usage:industry Model No.:QXX Series Fuel:coal, lignite, slag Usage:industry Pressure:low pressure

Type:forced circulation Place of Origin:Henan,China (Mainland) Output:64MW Structure:water tube Style:a verticaltype with double drums

QXX Series 64MW Circulating Fluidized Bed Boiler is circulating fluidized bed hot water boiler. It is forced circulation, safe and reliable.

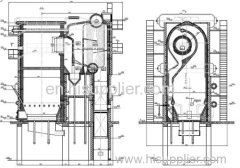

QXX Series 64MW Circulating Fluidized Bed Boiler is forced circulating fluidized bed hot water boiler. Convection heating surface layout convection tube between the upper and lower drum form, except economizer.So that the boiler has a large water capacity.Whena sudden power outage ,it can play a buffer role in enhancing their ability to protect the boiler.

QXX Series 64MW Circulating Fluidized Bed Boiler has the characteristics:

1.combustion efficiency and boiler thermal efficiency is very high.

2.Conducive to ash utilization.It improves economic efficiency.

3.Combining the splitter, gray circulatory system and the chamber as one, it compacts and looks neat appearance.

4.Separation is constitute of the membrane wall and the thin high-temperature resistant material, it is effectively preventing coking separator, the separator is stable.

5. external temperature of separator is low, heat loss isless.

6. It can start and stop the boiler in a relatively short period of time.

7. Back to the discharge ports are more, back to the material evenly. Using a porous wall semi-gravity valve feedback unit, so it is stable and reliable for backing to the material, it is low failure rate.

\basic characteristics of QXX Series 64MW Circulating Fluidized Bed Boiler

1.boiler specification

rated thermal power 64MW

rated outlet water temperature 130℃

rated water pressure 1.25MPa

rated inlet water temperature 70℃

exhaust gas temperature 146℃

cool air temperature 20℃

thermal efficiency 85.3%

2. Design fuel is lignite and slag. low calorific value of fuel is 9587.8KJ/Kg. Combustible volatile is about 24.4%.

3. The particle diameter of the fuel into the furnace is 0 - 10mm, andparticle diameter of less than 2mm is less than 30%.

4. Applicable fuel is anthracite, bituminous, lignite, lean coal, and gas-making slag mixed with the fuel. Low calorific value of fuel is 10000kJ/kg ~ 26000kJ/kg.

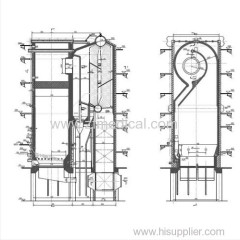

\Introduction to the structure of QXX Series 64MW Circulating Fluidized Bed Boiler

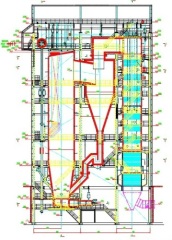

QXX Series 64MW Circulating Fluidized Bed Boiler adopts double drum transverse structure, fuel switch from coal feeder into the furnace,the fuel is burned withair which is sent from the isobaric bellows, combustion flue gas upward into the horizontal cyclone, cyclone is composition by the three films type water cool wall, to ensure reliable operation of the separator. Flue gas fly ash due to inertia force is separated from the road by the loose material back into the furnace to circulate air combustion, greatly improving the combustion efficiency. After the separation of gas from the cyclone outlet, from top to bottom through the U-shaped flue turn, further separation of the particles in the flue gas, and then enter the pipe economizer, economizer arrangement for the two, after scouring the flue gas economizer into the air preheater, and finally by the dust from the fan into the chimney. QXX Series 64MW Circulating Fluidized Bed Boiler ventilation adopts the balanced ventilation of blowers and ID fans.

A new generation of water-cooled horizontal separator circulating fluidized bed boiler technology competitive advantages:

While improving the water and keeping the original horizontal separator circulating fluidized bed boiler ,Zhengzhou Boiler Co.,Ltd

Innovate technological,which is based in science, principle of service users.In the practice of good results after the market, the main performance is as follows:

1. boiler increase waterwall tube of the front wall and the back wall, lowering the temperature of the front and back wall to protect the furnace wall, to extend the running time of the boiler.

2. boiler increase secondary air of the front wall and the back wall, the formation of wind arch, while strengthening the furnace flue gas disturbance, improving fuel burn rate once.

3. boiler adopts a new water-cooled furnace roof structure, to resolve the boiler roof leakage and collapse problems, the overall out of factory methods, to short the boiler installation time, to extend the running time of the boiler, in order to maximize the economic benefits of increased user.

64MW Circulating Fluidized Bed Boilers are circulating fluidized bed hot water boiler. It isforced circulation, safe and reliable.

64MW Circulating Fluidized Bed Boilers are circulating fluidized bed hot water boiler. It isforced circulation, safe and reliable.

Usage:industry

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

64MW Circulating Fluidized Bed Boilers are circulating fluidized bed hot water boiler. It isforced circulation, safe and reliable.

Usage:industry