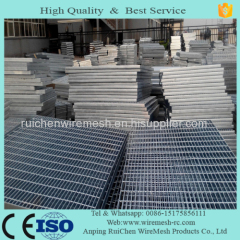

Hot dip Galvanized Steel Grating

| Min. Order: | 1 Square Meter |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 500000 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PVC Coated Gabion Box |

Product Detail

| Production Capacity: | 500000 |

|---|

Product Description

Hot dip galvanized frame lattice:

1) Galvanized frame lattice, usually the first to carry out anti-rust treatment. Before it is produced. In the production process is usually divided into hot-dipped galvanized and electro galvanized galvanized ,

Hot dip galvanized steel grating production process and by load flat steel bar at certain distances, at high pressure resistance welding machine welded together on the original plate, the cutting, incision, opening, edging and other processes from customer requirementsthe finished product, and then through hot-dip galvanizing treatment.

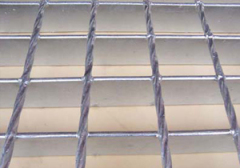

(1) hot dip galvanized steel grating flat center spacing: According to distinguish between series: Series 1 30mm; Series 2 is 40mm; Series 3 is 60mm.

(2) hot dip galvanized steel grating bar center distance: Series 1 100mm, Series 2 is 50mm..Other specifications can be made under customers' order.

(3) hot dip galvanized steel, flat steel grid plate: Material for the Q235A or stainless steel, a common plane type, tooth type and section I slip type.Common specifications are 20 * 5,25 * 5,25 * 3,32 * 5,32 * 5.40 * 5.40 * 3,50 * 5,65 * 5,75 * 6,100 * 8,100 * 10and so on.

(4) hot dip galvanized steel grating bar: material Q235A, or 304 stainless steel for the bar, twisted square steel, square steel or six angles.Twisted square steel plate garden by drawing upon and twisted from side mode, the common specifications are 5 * 5,6 * 6,8 * 8mm and so on.

Hot dip galvanized steel grating features:

1. High-strength light structure, the use of strong bonding grid structure, which makes high-strength galvanized steel grating with a carrying capacity, and lightweight structure.

2. Beautiful appearance, durable, after the surface of hot dip galvanized after processing them with very good corrosion resistance, but also can keep the surface shiny appearance.

3. With good ventilation, lighting, cooling, explosion-proof and anti-skid properties, and maintain a certain performance against product contamination.

1) Galvanized frame lattice, usually the first to carry out anti-rust treatment. Before it is produced. In the production process is usually divided into hot-dipped galvanized and electro galvanized galvanized ,

Hot dip galvanized steel grating production process and by load flat steel bar at certain distances, at high pressure resistance welding machine welded together on the original plate, the cutting, incision, opening, edging and other processes from customer requirementsthe finished product, and then through hot-dip galvanizing treatment.

(1) hot dip galvanized steel grating flat center spacing: According to distinguish between series: Series 1 30mm; Series 2 is 40mm; Series 3 is 60mm.

(2) hot dip galvanized steel grating bar center distance: Series 1 100mm, Series 2 is 50mm..Other specifications can be made under customers' order.

(3) hot dip galvanized steel, flat steel grid plate: Material for the Q235A or stainless steel, a common plane type, tooth type and section I slip type.Common specifications are 20 * 5,25 * 5,25 * 3,32 * 5,32 * 5.40 * 5.40 * 3,50 * 5,65 * 5,75 * 6,100 * 8,100 * 10and so on.

(4) hot dip galvanized steel grating bar: material Q235A, or 304 stainless steel for the bar, twisted square steel, square steel or six angles.Twisted square steel plate garden by drawing upon and twisted from side mode, the common specifications are 5 * 5,6 * 6,8 * 8mm and so on.

Hot dip galvanized steel grating features:

1. High-strength light structure, the use of strong bonding grid structure, which makes high-strength galvanized steel grating with a carrying capacity, and lightweight structure.

2. Beautiful appearance, durable, after the surface of hot dip galvanized after processing them with very good corrosion resistance, but also can keep the surface shiny appearance.

3. With good ventilation, lighting, cooling, explosion-proof and anti-skid properties, and maintain a certain performance against product contamination.

5) hot dip galvanized steel grating uses: widely used in the industry of petrochemical, power plants, water plants, sewage treatment plants, municipal engineering, environmental engineering and other fields.Used to be as the platforms, walkways, bridge, ladders, fences,