Water well screen

10.0~1000.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C, T/T, Cash |

| Supply Ability: | 6000meters/month |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | LZL-3 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HUADONG SCREEN |

| OD: | 7 |

| Wire height: | 5.0mm |

| Wire width: | 3.2mm |

| Materail: | SS304 |

| Unit length: | 6meters |

| Rod: | 3.5 |

| Rod's number: | 38nos |

| Slots: | 0.635mm |

| Production Capacity: | 6000meters/month |

| Packing: | Plastic warpped the pipe and woods support |

| Delivery Date: | According to the order quantity |

Product Description

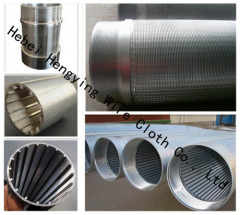

We also called Continous slot screen. With sectional construction, we have built screens up to 2.6m in diameter and 16 m long. Each Longzhonglong screen can be up to 5.9 m in continuous length. A wide range of external wrap wire and internal support rod shapes and sizes lets our design engineers build you a screen that's the perfect fit for your application. Our screen cylinders are used for a variety of filtration, media retention and dewatering applications. Screen slots are sized to admit fluid flow while excluding solids.

With such packing materials as gravels filled into the space between their outer and inner, double prepacked screens, mainly used in oil wells, gas well and water well, well make downhole operation unnecessary and better sand prevention. Catalysts or microbicides packed in the inter lyers of screens contribute to chemical production and industrial sterilization.

Specialty steel screens can take nearly any form, and fit nearly any liquid/solid separation need or architectural concept: Other materials such as carbon steel are used in making Longzhong long screens. In addition, we offer economical, efficient screens with extremely large inner diameter to satisfy the requirement of our customs. Our steel screens can also be custom-treated with powder coating, aluminizing, galvanizing electropolishing, chrome plating and many other processes.

Normal size (mm) | ID (mm) | Thickness (mm) | Coupling OD (mm) |

50 | 38 | 4 | 52 |

60 | 50 | 4 | 62 |

70 | 60 | 4 | 72 |

80 | 70 | 4 | 82 |

90 | 80 | 4 | 92 |

108 | 98 | 4 | 110 |

127 | 108 | 6 | 129 |

146 | 136 | 4 | 161 |

159 | 140 | 6 | 161 |

178 | 168 | 4 | 180 |

219A | 200 | 6 | 221 |

219 | 209 | 4 | 234 |

245A | 224 | 6 | 246 |

245 | 235 | 4 | 260 |

273 | 252 | 6 | 275 |

325 | 306 | 6 | 326 |

377 | 358 | 6 | 379 |

426 | 406 | 6 | 428 |

478 | 458 | 6 | 480 |

529 | 508 | 6 | 530 |

630 | 610 | 6 | 632 |

720 | 700 | 6 | 722 |

800 | 780 | 6 | 802 |

1000 | 980 | 6 | 1002 |

1200 | 1180 | 6 | 1202 |

.gif)