Pultruded Gratings

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Window Screening, Stainless Steel Wires, Square Wire Meshes, Brass Wire Meshes, Welded Wire Meshes |

Product Detail

| Model No.: | full |

|---|---|

| Means of Transport: | CIF, FOB, CNF |

| Brand Name: | Jinghua |

| Featur Strength: | Superior strength and stiffness |

| Corrosion Resistance: | Superior to stainless steel, aluminum and galvanized gratings. |

| Fabrication Features: | Allow for greater use versatility with longer spans which may reduce scrap loss. |

| Safety Surface: | A coarse epoxy grit bonded to both the bearing and cross bars (unless noted). |

| Packing: | in cartons |

| Delivery Date: | within 30 days after receiving prepayments |

Product Description

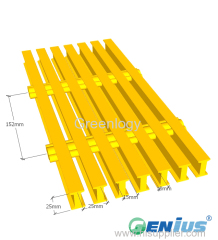

Pultruded Grating is used in installations where exceptional load bearing and uninterrupted spans need to be bridged. The high ratio of grassfire to resin content guarantees exceptional mechanical strength. Pultruded grating is available in 25mm, 38mm, 50mm, 75mm and 100mm thicknesses, I beam & T bar pultruded profiles and with 18% 30% 33% 35% 40% 50% & 60% open surface area.

- FeaturStrength: Pultruded Grating products offer superior strength and stiffness. Since glass is the key contributor to structural performance, pultruded offers the highest strength to unit weight ratio.

- Corrosion Resistance: The degree of corrosion resistance for pultruded grating is superior to stainless steel, aluminum and galvanized gratings.

- Fabrication Features: Many panel sizes allow for greater use versatility with longer spans which may reduce scrap loss.

- Safety Surface: The walking surface of most Pultruded Grating has a coarse epoxy grit bonded to both the bearing and cross bars (unless noted).

Features and Benefits:

- maintenance free

- standard installation methods

- easy to install

- built-in resiliency

- environmentally safe

- corrosion resistance

- electrical and thermal insulation

- electromagnetically transparent

- part integration

- inherent color

- dimensional stability over wide temperature ranges

Pultruded grating

Our series of pultruded grating is made by a particular assembly process, which using"I" shape as its main load-bearing part and using special rod to go through the bearing bar. Our pultruded grating Includes standard grating and custom grating, custom grating can be designed to meet customer's requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

Choice of pultruded grating

Resin choice

Jinghua series of pultruded grating has three resin types: GP, ISG, and VE. Different types can meet the requirement of corrosion-resistance properties in different working environments and conditions.

Our series of pultruded grating is made by a particular assembly process, which using"I" shape as its main load-bearing part and using special rod to go through the bearing bar. Our pultruded grating Includes standard grating and custom grating, custom grating can be designed to meet customer's requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

Choice of pultruded grating

Resin choice

Jinghua series of pultruded grating has three resin types: GP, ISG, and VE. Different types can meet the requirement of corrosion-resistance properties in different working environments and conditions.