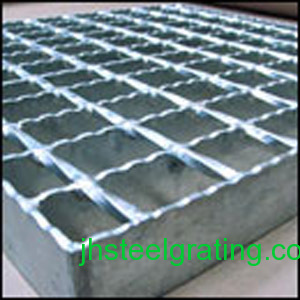

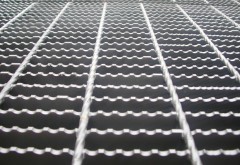

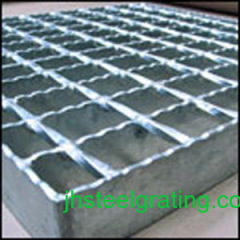

serrated steel gratings

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Window Screening, Stainless Steel Wires, Square Wire Meshes, Brass Wire Meshes, Welded Wire Meshes |

Product Detail

| Means of Transport: | CIF, FOB |

|---|---|

| Brand Name: | jinghua |

| surface treatments: | bare steel (no finish), painted with one coat of manufacturers red, black or silver paint, or hot dip galvanized |

| Packing: | in cartons |

| Delivery Date: | within 30 days after your orders |

Product Description

Introduction:

The excellent self-cleaning characteristics of serrated steel grating make it suitable for the majority of applications. In the presence of fluids or materials that could cause the top surface of the grating to become wet or slippery, specification of the optional serrated surface should be considered. When serrated grating is specified, the bearing bar depth must be 1/4" greater than the sizes shown on the load tables to provide the equivalent strength of non-serrated gratings..

The excellent self-cleaning characteristics of serrated steel grating make it suitable for the majority of applications. In the presence of fluids or materials that could cause the top surface of the grating to become wet or slippery, specification of the optional serrated surface should be considered. When serrated grating is specified, the bearing bar depth must be 1/4" greater than the sizes shown on the load tables to provide the equivalent strength of non-serrated gratings..

Finishes:

Steel grating is usually provided with one of three finishes, bare steel (no finish), painted with one coat of manufacturers red, black or silver paint, or hot dip galvanized in accordance with ASTM A-123. Aluminum products are commonly supplied mill finish but they are also available with optional chemically cleaned or anodized finishes. Due to discoloration that occurs during welding and fabrication, Stainless Steel grating products typically require secondary finishing

Steel grating is usually provided with one of three finishes, bare steel (no finish), painted with one coat of manufacturers red, black or silver paint, or hot dip galvanized in accordance with ASTM A-123. Aluminum products are commonly supplied mill finish but they are also available with optional chemically cleaned or anodized finishes. Due to discoloration that occurs during welding and fabrication, Stainless Steel grating products typically require secondary finishing