.jpg)

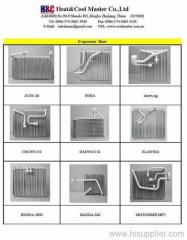

Evaporator

| Place of Origin: | India |

|---|

Company Profile

| Location: | India |

|---|

Product Detail

| Model No.: | E-205 |

|---|

Product Description

IEC FABCHEM LIMITED

We are pleased in introducing ourselves as the leading manufacturers and suppliers of the following industrial equipments.

Gas chlorination system, chlorinator, electro chlorinator, electro chlorination system, chlorine scrubber, chlorine handling accessories, chlorine vaporizer, chlorine evaporator, ammonia vaporizer, sulphurdioxide vaporizer, sulphurtrioxide vaporizer.

We are focused on timely delivery of our product and service to the best, beyond customer expectations.

For more details about our products and service please visit our website atReputation:

We are Indian government registered an ISO 9001:2000 company

We are Indian government registered an ISO 9001:2000 company

We are trustworthy in this field for more than forty seven years of excellence and undergo projects in thermal power plants and water treatment sectors all over India.

Focus:

We are reputed leading company in the manufacturing of different chlorination systems. We are actively looking for young entrepreneurs or trading agents or exporters to widespread our firm worldwide.

We welcome joint ventures and partnership deeds in abroad. Be free in contacting us for further details and inquiries.

Contact Details:

Yours

RAJKUMAR

(Director)

Note: Please find the attachment of our company's complete profile and credentials with performance certificates and product details.

|

GENERAL

Chlorine is available in liquid form but is generally utilized as a gas. Chlorine gas is normally withdrawn directly from containers when withdrawal rates do not exceed the container vaporization rate. If a large quantity of chlorine gas is required, Chlorine evaporators are used. OPERATING PRINCIPLE Liquid chlorine is transferred from its source to the evaporator chamber by container pressure. |

This chamber is immersed in a controlled heated water bath, which increases the temperature of the liquid, causing it to boil. Liquid enters the chamber and maintains the required liquid level necessary to meet the vaporization rate for the gas demand.A change in gas demand will cause the chlorine liquid level to adjust. The gas released, rises through baffles and superheated as it leaves the chamber. A superheated gas is required to prevent gas reliquefaction in process piping.

INSTALLATION

Location

The evaporator should be located close to the source if possible. The length of liquid and gas lines should be kept to a minimum. Container room with provisions for exhausting gas, if a leak develops, is ideal. A lifting device above the evaporator is recommended for servicing the chamber.

Location

The evaporator should be located close to the source if possible. The length of liquid and gas lines should be kept to a minimum. Container room with provisions for exhausting gas, if a leak develops, is ideal. A lifting device above the evaporator is recommended for servicing the chamber.

CATHODIC PROTECTION

The water wetted surfaces of the evaporator are protected against corrosion by two sacrificial anodes. The anodes being the most active metal in the evaporator will suffer corrosion and supply the electrical current needed to protect the structure.

SAFE & SELF ADJUSTABLE CAPACITY

Evaporator cannot fill with liquid to build excessive pressure because its liquid level is self-adjusting. An automatic shut-off and pressure reducing valve is included. A water temperature control thermostat and contacts for low water temperature alarm are also included. Other devices, as optional are high water temperature alarm switch; a gas temperature gauge on the instrument panel; and a low water alarm actuated by a level probe.

Because the evaporation rate is self-adjusting, the proper liquid level is always maintained in the gas chamber. The proper water bath level is maintained by a make-up-water flow meter with a manual control valve. Or, an automatic make-up-water level system is optional, Level probes in this resistance-type system open and close a solenoid valve to maintain the proper water-bath level.

RELIABLE OPERATION FULLY AUTOMATIC

This is a water immersed-tank heat exchanger specifically designed to evaporate liquid chlorine. Sulfur dioxide of ammonia. Heat from a hot water bath converts liquid to gas. immersion type electric heaters supply the heat.

The evaporator is designed for safety. It requires minimum maintenance. With several options, operation can be fully automatic.

| Model No. | Capacity Kg/hr. Gas | Power Consumption | ||

| E 205 | Cl 2 | SO 2 | NH 3 | KW |

| 1 | 50 | 32 | 11 | 5 |

| 2 | 100 | 65 | 22 | 10 |

| 3 | 180 | 120 | 35 | 18 |

| 4 | 360 | 240 | 75 | 36 |

| CL2 -CHLORINE | SO2-SULFUR DIOXIDE | NH3-AMMONIA | ||||

Standard equipment

Cabinet

Water chamber, level controlled water supply.

Vapourizing chamber

Superheating Chamber

Water level indicator

Gas temperature indicator

Water temperature controller

Min. water temperature switch

Max. water temperature switch

Immersion heater

Cabinet

Water chamber, level controlled water supply.

Vapourizing chamber

Superheating Chamber

Water level indicator

Gas temperature indicator

Water temperature controller

Min. water temperature switch

Max. water temperature switch

Immersion heater