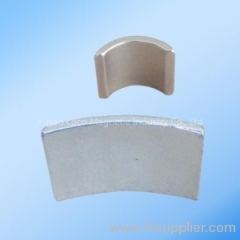

About Bonded NDFEB rotor magnet:

item:16756-001 REV A

Description:

material: 16-10(12 MGOe)

Binder: epoxy resin

Coating: grey epoxy

Rohs compliant

If you are interested in ,please contact us.

| Product name | Black epoxy coating bonded ndfeb neodymium magnets |

| Material | Bonded Neodymium-Iron-Boron |

| Grade | BN-6 |

| Coating | Black epoxy |

| Shape | Ring |

| Dimensional Tolerance | +/-0.05mm |

| Magnetization Direction | 4-Poles on OD |

| Temperature Range (Deg C) | 0 to 100 |

| Remanence(Br) | 550-620 mT |

| Coercivity | >600 kA/m |

| (BH) max | 44-56 Kj/m³ |

| Pull strength | Approx. 5 lbs |

| Advise | This is not a toy. Inappropriate use might cause injury. |

Bonded Neodymium magnets are made of the powerfurl Nd-Fe-B material mixed into an epoxy binder. The mix is appropximately 97 vol% magnet material to 3 vol% epoxy. The manufacturing process involves combining Nd-Fe-B powder with an epoxy binder and compressing the mixture in a press and curing the part in an oven. Since the material is formed by compression bonding, the dimension typically vary. Our dimensional tolerance is aout +/- 0.05mm.

Bonded Neodymium material is isotropic, so it can be magnetized through any direction, including multi-polar arrangements. Because the material is in an epoxy binder, it can be machined on a mill or ceramic magnet materials. Significant size reductions can be achieved because Bonded Neodymium material is approximately 3 times stronger than ceramic magnet material. In addition, since Bonded Neodymium material is isotropic, it can be magnetized multi-polar, such as a N-S-N pattern on the outer diameter of a ring.