Sinkhole Ring NdFeB Magnet

| Min. Order: | 10 Kilogram |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | D12Xd9X2 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Motor Magnet |

| Shape: | Coil |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HONY |

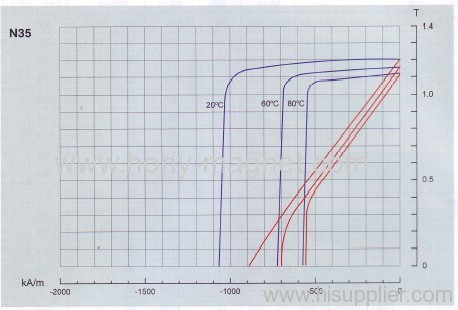

| Grade: | N35 |

| Production Capacity: | 10000 |

| Packing: | carton or pallet |

| Delivery Date: | 30DAYS |

Product Description

We are the factory of NdFeB RING Magnets,Sinkhole Ring NdFeB Magnet, Peculiar Ring NdFeB Magnet, Ring Neodymium Magnet,Ring sintered NdFeB Magnet,Sintered NdFeB Magnet and so on.

We produce Cylinder NdFeB magnets/Cylinder Sintered NdFeB Magnets

The Cylinder NdFeB Magnets/Cylinder Neodymium Magnet we are supplying are with following t specifications:

1. Sintered NdFeB Magnets with different grades of: N35,N38,N40,N42,N45,N48,N50,N52(M,H,SH,UH,EH,AH) etc.

2. Working temperature for Sintered NdFeB Magnets: from 80 degree centigrade to 230 degree centigrade.

3. Can be magnetized according to the requirements of clients.( thickness, width, length...)

4. Coatings: Ni, Zn, epoxy, gold, silver, Cu and so on(as per the requirements).

5. NdFeB Magnetic Material has super strong magnetic force and high intrinsic coercive force.

6. With precise tolerance.

Application for cylinder NdFeB Magnets/Cylinder Neodymium Magnet:

Magnetic separator, Sensors, Wind generators, Vibration motors, DC motors, Servo motors, Linear motors, VCM, MRI, Loudspeakers, Linear actuators, drives, toys, bags, household appliances, microphone parts, transmission equipments...

Features of cylinder NdFeB Magnets/Cylinder Neodymium Magnet:

Neodymium magnets are mainly made from neodymium ,iron, and boron. It is the ideal magnetic material in the world till now and have been used universally in the world . It has super strong magnetic force and high intrinsic coercive force and after concocting , it can stand very high working temperature, as high as 200 centigrade.

All These special features of NdFeB material make it irreplaceable in the world.

So till now, it has universally been used in electronics, aviation, motors, automobiles, medical apparatus, transmission machine... and even in many details of our everyday life.

NdFeB magnet, Neodymium Magnet, the third generation of rare-earth permanent magnet, is the most powerful and advanced commercialized permanent magnettoday. NdFeB has high coercive force, high energy and high performance/ cost ratio. It can be formed into various sizes and widely used in many fields such as aviation, electronics, instruments, meters, machines and medical instrument.

Our NdFeB Magnet, Sintered Neodymium Magnet and Neodymium Magnet are available in a variety of shapes and sizes, including blocks, rings, arcs, segments and disc. We have 6 grades, namely N, M, H, SH, UH and EH. In order to ensure the highest quality products, we have founded a R&D center and quality control center for solving the problems in prodcution and quality.

Furthermore, all of our NdFeB Magnet, Sintered Neodymium Magnet, are manufactured based on the ISO9001 and QS-9000 quality standards. Therefore, we surpass our competitors in the stability of quality and superiority of property.

Br mT (kGs) | Hcb kA/m (kOe) | Hcj kA/m (kOe) | (BH)max kJ/m3 |

| |

N27 | 1030-1080(10.3-10.8) | ≥ 796( ≥ 10.0) | ≥ 955( ≥ 12) | 199-231(25-29) | 80 ℃ |

N30 | 1080-1130(10.8-11.3) | ≥ 796( ≥ 10.0) | ≥ 955( ≥ 12) | 223-247(28-31) | 80 ℃ |

N33 | 1130-1170(11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 955( ≥ 12) | 247-271(31-34) | 80 ℃ |

N35 | 1170-1220(11.7-12.2) | ≥ 868( ≥ 10.9) | ≥ 955( ≥ 12) | 263-287(33-36) | 80 ℃ |

N38 | 1220-1250(12.2-12.5) | ≥ 899( ≥ 11.3) | ≥ 955( ≥ 12) | 287-310(36-39) | 80 ℃ |

N40 | 1250-1280(12.5-12.8) | ≥ 907( ≥ 11.4) | ≥ 955 ( ≥ 12) | 302-326(38-41) | 80 ℃ |

N42 | 1280-1320(12.8-13.2) | ≥ 915( ≥ 11.5) | ≥ 955( ≥ 12) | 318-342(40-43) | 80 ℃ |

N45 | 1320-1380(13.2-13.8) | ≥ 923( ≥ 11.6) | ≥ 955 ( ≥ 12) | 342-366(43-46) | 80 ℃ |

N48 | 1380-1420(13.8-14.2) | ≥ 923( ≥ 11.6) | ≥ 876( ≥ 12) | 366-390(46-49) | 80 ℃ |

N50 | 1400-1450(14.0-14.5) | ≥ 796( ≥ 10.0) | ≥ 876( ≥ 11) | 382-406(48-51) | 60 ℃ |

N52 | 1430-1480(14.3-14.8) | ≥ 796( ≥ 10.0) | ≥ 876( ≥ 11) | 398-422(50-53) | 60 ℃ |

30M | 1080-1130(10.8-11.3) | ≥ 796( ≥ 10.0) | ≥ 1114 ( ≥ 14) | 223-247(28-31) | 100 ℃ |

33M | 1130-1170(11.3-11.7) | ≥ 836( ≥ 10.5) | ≥ 1114( ≥ 14) | 247-263(31-33) | 100 ℃ |

35M | 1170-1220(11.7-12.2) | ≥ 868( ≥ 10.9) | ≥ 1114( ≥ 14) | 263-287(33-36) | 100 ℃ |

38M | 1220-1250(12.2-12.5) | ≥ 899( ≥ 11.3) | ≥ 1114( ≥ 14) | 287-310(36-39) | 100 ℃ |

40M | 1250-1280(12.5-12.8) | ≥ 923( ≥ 11.6) | ≥ 1114( ≥ 14) | 302-326(38-41) | 100 ℃ |

42M | 1280-1320(12.8-13.2) | ≥ 955( ≥ 12.0) | ≥ 1114( ≥ 14) | 318-342(40-43) | 100 ℃ |

45M | 1320-1380(13.2-13.8) | ≥ 995( ≥ 12.5) | ≥ 1114 ( ≥ 14) | 342-366 (43-46) | 100 ℃ |

48M | 1360-1430(13.6-14.3) | ≥ 1027( ≥ 12.9) | ≥ 1114( ≥ 14) | 366-390(46-49) | 100 ℃ |

50M | 1400-1450(14.0-14.5) | ≥ 1033 ( ≥ 13.0) | ≥ 1114( ≥ 14) | 382-406(48-51) | 100 ℃ |

30H | 1080-1130(10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1353( ≥ 17) | 223-247(28-31) | 120 ℃ |

33H | 1130-1170(11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1353( ≥ 17) | 247-271(31-34) | 120 ℃ |

35H | 1170-1220(11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1353( ≥ 17) | 263-287(33-36) | 120 ℃ |

38H | 1220-1250(12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1353 ( ≥ 17) | 287-310(36-39) | 120 ℃ |

40H | 1250-1280(12.5-12.8) | ≥ 923( ≥ 11.6) | ≥ 1353( ≥ 17) | 302-326(38-41) | 120 ℃ |

42H | 1280-1320(12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1353( ≥ 17) | 318-342(40-43) | 120 ℃ |

45H | 1300-1360(13-13.6) | ≥ 963( ≥ 12.1) | ≥ 1353 ( ≥ 17) | 326-358(43-46) | 120 ℃ |

48H | 1370-1430(13.7-14.3) | ≥ 995( ≥ 12.5) | ≥ 1353( ≥ 17) | 366-390(46-49) | 120 ℃ |

30SH | 1080-1130(10.8-11.3) | ≥ 804( ≥ 10.1) | ≥ 1592( ≥ 20) | 223-247(28-31) | 150 ℃ |

33SH | 1130-1170(11.3-11.7) | ≥ 844( ≥ 10.6) | ≥ 1592( ≥ 20) | 247-271(31-34) | 150 ℃ |

35SH | 1170-1220(11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 1592( ≥ 20) | 263-287(33-36) | 150 ℃ |

38SH | 1220-1250(12.2-12.5) | ≥ 907( ≥ 11.4) | ≥ 1592( ≥ 20) | 287-310(36-39) | 150 ℃ |

40SH | 1240-1280(12.5-12.8) | ≥ 939( ≥ 11.8) | ≥ 1592( ≥ 20) | 302-326(38-41) | 150 ℃ |

42SH | 1280-1320(12.8-13.2) | ≥ 987 ( ≥ 12.4) | ≥ 1592 ( ≥ 20) | 318-342(40-43) | 150 ℃ |

45SH | 1320-1380(13.2-13.8) | ≥ 1003 ( ≥ 12.6) | ≥ 1592( ≥ 20) | 342-366 (43-46) | 150 ℃ |

28UH | 1020-1080 (10.2-10.8) | ≥ 764 ( ≥ 9.6) | ≥ 1990 ( ≥ 25) | 207-231(26-29) | 180 ℃ |

30UH | 1080-1130 (10.8-11.3) | ≥ 812( ≥ 10.2) | ≥ 1990( ≥ 25) | 223-247(28-31) | 180 ℃ |

33UH | 1130-1170(11.3-11.7) | ≥ 852( ≥ 10.7) | ≥ 1990 ( ≥ 25) | 247-271(31-34) | 180 ℃ |

35UH | 1180-1220 (11.8-12.2) | ≥ 860 ( ≥ 10.8) | ≥ 1990( ≥ 25) | 263-287(33-36) | 180 ℃ |

38UH | 1220-1250(12.2-12.5) | ≥ 876 ( ≥ 11.0) | ≥ 1990( ≥ 25) | 287-310(36-39) | 180 ℃ |

40UH | 1240-1280 (12.5-12.8) | ≥ 899( ≥ 11.3) | ≥ 1990( ≥ 25) | 302-326(38-41) | 180 ℃ |

28EH | 1040-1090(10.4-10.9) | ≥ 780( ≥ 9.8) | ≥ 2388( ≥ 30) | 207-231(26-29) | 200 ℃ |

30EH | 1080-1130 (10.8-11.3) | ≥ 812 ( ≥ 10.2) | ≥ 2388 ( ≥ 30) | 223-247 (28-31) | 200 ℃ |

33EH | 1130-1170(11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 2388 ( ≥ 30) | 247-271 (31-34) | 200 ℃ |

35EH | 1170-1220(11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 2388( ≥ 30) | 263-287(33-36) | 200 ℃ |

38EH | 1220-1250(12.2-12.5) | ≥ 899( ≥ 11.3) | ≥ 2388( ≥ 30) | 287-310(36-39) | 200 ℃ |