Bonded Magnet Ring for Electric Vibration Motor

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 1000000/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Industrial Magnet |

| Shape: | Disc |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HONY |

| Type: | Bonded neodymium half ring magnet |

| Application: | Moto Magnet |

| Working temperature: | High up to 150℃ |

| Coating: | Grey Epoxy |

| Coating Thickness: | 25-50 |

| Shape: | ring |

| Production Capacity: | 1000000/month |

| Packing: | carton |

| Delivery Date: | 25 |

Product Description

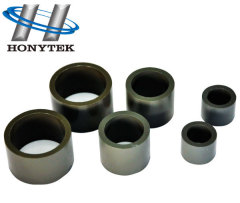

Bonded Magnet Ring for Electric Vibration Motor

Material:

Quick-quenched NdFeB magnetic powder with bonding agent.

Grade:

BN-6 to BN-12

Type:

Compression molding magnets & Injection molding magnets

Coating:

1. Black, grey Epoxy;

2. Prylene.

Magnetization:

Thickness Magnetization, Radiation Magnetization, Multi-pole Magnetization

Performance:

Br T: 0.55-0.80

(BH)max k J/M3 (MGOe): 44-92 (5.5-11.5)

Tw 0C: 110-150

Produts Tech:

Powder--Belending--Granulation--Compaction--Curing--Refining--Coating--Magnetization--Packing

Features:

1. High precision;

2. Excellent magnetic properties;

3. Stable working temperature;

4. Good corrosion-resistance and nice surface.

The complete combination of injecting process and high-property rare-earth powder makes it possible to form easily the anisotropic(especially radial anisotrotropic)super-thin ring or block magnets in complex shapes.The products can be formed in a unit together with other components.This process provides high precision and high acceptable rate of products.

Usages:

1. The compression molding magnets, as for simple mould and high magnetic properties, are widely used in stepping motor, CD-ROM spindle motor, general motor, vibrating motor, pick-up, HDD spindle motor, and FDD spindle motor.

2. The injection molding magnets, as for complex mould, magnetic properties around 6 to 7 MGOe, and highly consistency, are widely used in electric expansion valve, air-condition motor etc,.

Bonded Magnet Ring for Electric Vibration Motor

Bonded Magnet Ring for Electric Vibration Motor

| Magnet Information | |||

| Description | Bonded NdFeB Magnet | ||

| Material: | Quick-quenched NdFeB magnetic powder with bonding agent. | ||

| Shape: | Ring, Thin-wall ring, Disc, Cylinder, Segment, Irregular shapes…With special shape requirement, we have own R & D dept. to support | ||

| Coating: | Anti-Rust Oil, Spray Rolling, Black, Grey Epoxy, Special Soak | ||

| Magnetic Performance Sheet | |||

| Grade | Remanence (Br) | Coercivity(BH) max kJ/m3 | Temperature |

| mT | KJ/M3 | (Tw°C) | |

| kGs | MGOe | ||

| BNP-6 | 0.55-0.62 | 44-56(5.5-7.0) | 100 |

| BNP-8L | 0.60-0.64 | 56-64(7.0-8.0) | 110 |

| BNP-8 | 0.62-0.69 | 64-72(8.0-9.0) | 120 |

| BNP-8SR | 0.62-0.66 | 64-72(8.0-10.5) | 150 |

| BNP-8H | 0.61-0.65 | 64-72(8.0-10.5) | 125 |

| BNP-9 | 0.65-0.70 | 70-76(8.8-9.5) | 120 |

| BNP-10 | 0.62-0.66 | 76-84(9.5-10.5) | 120 |

| BNP-11 | 0.70-0.74 | 80-88(10.0-11.0) | 120 |

| BNP-11L | 0.70-0.74 | 78-84(9.8-10.5) | 110 |

| BN-12 | 0.74-0.80 | 84-92(10.5-11.5) | 110 |

| Magnet Coating | |||

| Coating | Thickness (Microns) | Color | Resistance |

| Anti-Rust Oil | 1 | Trancparency | Temporary Protection |

| Spray Rolling | 10-50 | Common Black or other color | 24 hours of salt spray test |

| Epoxy | 25-50 | Grey, Black | 48 hours of salt spray test, 240 hours of constant temperature and humidity |

| Parylene | 10-50 | Trancparency | 200 hours of Salt Spray. Superior Against Solvents, Fungi and Bacteria |

Bonded Magnet Ring for Electric Vibration Motor

Delivery

All available shipping ways could be applied, by courier, by air or by sea.

Appointed shipping company or our own forwarders all could be used in shipment.

Full-way tracking the cargos for you before the goods arrive.

Buyer's Guide

In order to quote you the best price quickly, please provide the following information:

1.Product size,grade,coating,etc.

2.Order quantity;

3.Attached the drawings if customized

4.Any special packing or other requirements

Our advantage

1. Fast reply: all your enquiry will be replied within 24 hours;

2. Reasonable price: we are direct manufacturer and able to offer better price;

3. Good quality: we are experienced in quality control;

4. Fast delivery time:7-20 days

FAQ

1:How long will you give me the reply?

we will contact you in 12 hours as soon as we can.

2:Could I get samples?

Yes,we have materials in stock to help you to get the samples as soon as we can.

3:How about the quality of the magnets?

We have the certification of ISO,CE and ROSH, we can send the certificate copy for your reference.

4:Could I visit your factory?

Yes, you are welcome to visit our factory.

.jpg)