ALNICO cylinder alnico magnet

| Min. Order: | 100 Kilogram |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20 tons monthly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Sintering NdFeB Block, NdFeB Ring Magnet, Irregular Magnet, Disk NdFeB Magnet, Ferrite Sphere Magnet |

Product Detail

| Model No.: | LN9 LNG12/13/37/40/44/52/60 LNGT28/18/32/40/60/36J |

|---|---|

| Means of Transport: | Ocean, Air |

| certificate: | ISO9001:2000 , ISO 14001:2004 |

| materials: | AlNiCo |

| shape: | cylinder |

| Production Capacity: | 20 tons monthly |

| Packing: | occording to customers is requiements |

| Delivery Date: | General deliverly for 10 days |

Product Description

Cylindrical AlNiCo can be applied in magnetic latching relay, watt-hour meters, water meters, counters, reed switch and sensors.

sintered AlNiCo

Raw materials → ingredients → magnetic powdering → pressing →sintered → heating → magnets test → → products test → packingCosting AlNiCo

Raw materials → ingredients → melting → costing → heating → magnets test → → products test → packing

AlNiCo cylinder magnet:

1. Certification: Products are manufactured according to ISO9001 quality system.

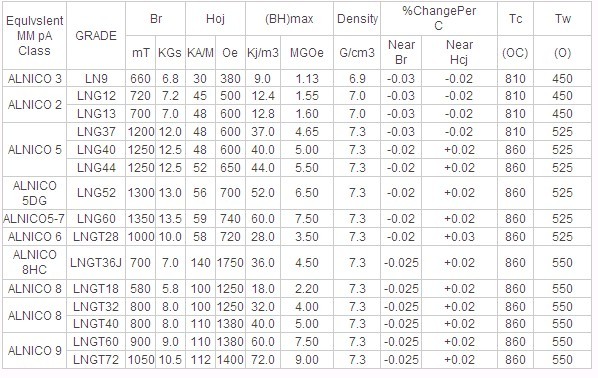

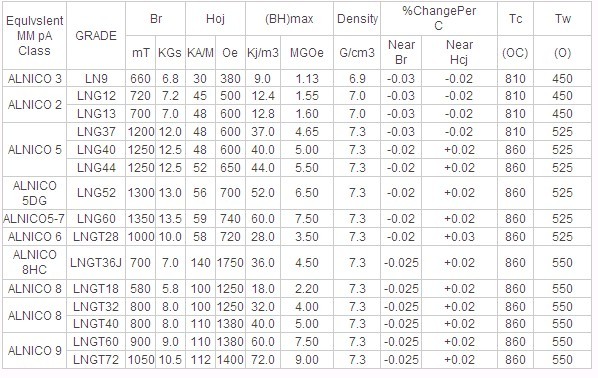

2. Properties:

High energies and relatively low coercivity.

Excellent ability to withstand extreme temperatures stability.

High working temp: 450-550 degree

Good corrosion resistance.

High mechanical strength.

3. Shapes: Various kinds or according to customers' requests

4. Grades: AlNiCo2, AlNiCo3, AlNiCo5, AlNiCo5DG, AlNiCo5-7, AlNiCo6, AlNiCo8HC, AlNiCo8, and AlNiCo9 (US standard)

5. Products manufactured according to ISO9001 quality system.

6. Applications: measuring instruments, flywheel generators and sensors, stepping motor and relays, flow and AVO meter, odometer of automobile and motorcycle, buzzer of mobile phone and so on.neodymium cylinder alnico magnet:

Key features:

1)Being manufactured by a powder metallurgy process,which utilise controlled atmosphere high temperature sintering to produce near net shape pats

2)Ideal for high temperature application up to 550°C

3)Having good corrsion resistance and a typical hardness of 50 Rockwell C,only machining possible grinding

4)Fine crystalline metallic struture,density ranges from 6.9g/cm³ to 7.3g/cm³

5)Adjusting materials and processing to produce both a standard range of magnetic properties or individually tailored alloys to meet customer specific requirementssintered AlNiCo

Raw materials → ingredients → magnetic powdering → pressing →sintered → heating → magnets test → → products test → packingCosting AlNiCo

Raw materials → ingredients → melting → costing → heating → magnets test → → products test → packing

.jpg)

.jpg)