Ferrite block type magnet

| Min. Order: | 100 Kilogram |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20 tons monthly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Sintering NdFeB Block, NdFeB Ring Magnet, Irregular Magnet, Disk NdFeB Magnet, Ferrite Sphere Magnet |

Product Detail

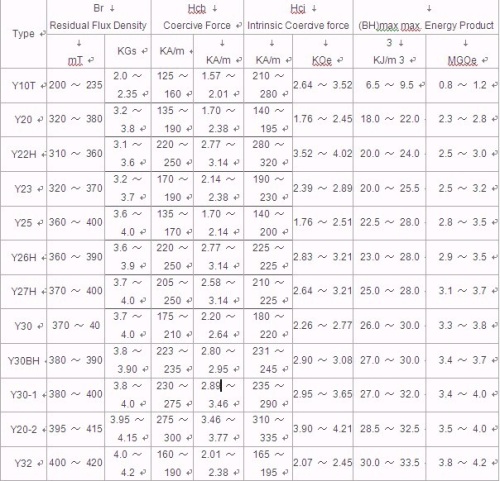

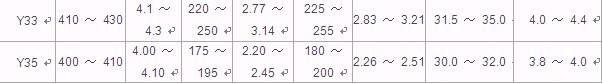

| Model No.: | Y10T/Y20/Y22H /Y26T/Y27H/Y30BH/Y30-1/Y20-2/Y35... |

|---|---|

| Means of Transport: | Ocean, Air |

| certificate: | ISO9001:2000 , ISO 14001:2004 |

| materials: | Ferrite |

| shape: | block |

| Production Capacity: | 20 tons monthly |

| Packing: | according to customers is requirements |

| Delivery Date: | General delivery for 10 days |

Product Description

Ferrite block type magnet

Features:

Features:

- Come in many sizes and type.

- Complete with coating:(Nickel, copper,zink or gold plated)

- They can be secured with M4 screw or other sizes of screws/hooks.

- The magnet is not magnetized on the threaded side but both poles are on the same side at the face.

- Magnetic surface strength surely high, approximately up to 3000 Gauss.

LTE other magnet accessories products:

- Permanent Magnet - various size with different magnetic strength

- Ferrite magnets

- Magnet Knife / Tool Holder

Production: powder metallurgy

Composition: Ba/Sro- Fe2O3

Performance: hard to be demagnetized and well performance in anticorrosion

Application: widely used and inexpensive.

The permanent ferrite

The permanent ferrite has been produced since 1950s. It is a ferromagnetic metallic oxide which is produced by powder metallurgy. It is divided into Ba and Sr. It can be molded into isotropic and anisotropic magnets its necessity of magnetic force. The permanent ferrite is hard to be demagnetized and anticorrosion, and the working temperature reaches 250 ℃, the Curie temperature reaches 450℃. It is a material which is hard but fragile and can be cut and processed by diamond grinding wheels or other molds. This kind of product is wildly used in magnetoelectric motors, sports equipments, medical equipments, aquatic equipments, loudspeakers and so on.

Our advantages:

The permanent ferrite has been produced since 1950s. It is a ferromagnetic metallic oxide which is produced by powder metallurgy. It is divided into Ba and Sr. It can be molded into isotropic and anisotropic magnets its necessity of magnetic force. The permanent ferrite is hard to be demagnetized and anticorrosion, and the working temperature reaches 250 ℃, the Curie temperature reaches 450℃. It is a material which is hard but fragile and can be cut and processed by diamond grinding wheels or other molds. This kind of product is wildly used in magnetoelectric motors, sports equipments, medical equipments, aquatic equipments, loudspeakers and so on.

Our advantages:

- In order to promote the development of environmental protection, our materials are in accordance with standards of International Environmental Organizations and ROHS.

- We are one of the companies who can produce the magnet of Br3900T,Hcj3900KA/m.

- We can produce any heteromorphic products, like round perforation, inner oval, U shaped, ladder-shaped, polygon and so on.

- Our effective quality monitoring system gives us the competitive advantages of quality.

- Our advanced ball milling equipments and unique technology can make sure that the powder are well-distributed and uniformity of its performance.

- The combination of international advanced electric furnace equipment and Steam sintered furnace equipment can make sure the uniformity in the sintered process.

The Process mapping

Test of presintered → secondary fine grinding→ molding→ sintered → grinding and cleaning→ checking and classifying→ packing →stocking test→ stocking→ final verification →delivery