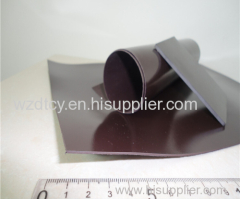

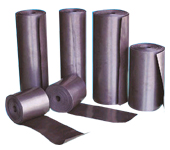

Strong Rubber magnets

| Min. Order: | 200 Kilogram |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 50 tons monthly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Sintering NdFeB Block, NdFeB Ring Magnet, Irregular Magnet, Disk NdFeB Magnet, Ferrite Sphere Magnet |

Product Detail

| Model No.: | YN-5T/YN-8/YN-10/YN-11/YN-13/YN-15/YN-11H |

|---|---|

| Means of Transport: | Ocean, Air |

| certificate: | ISO9001:2000 , ISO 14001:2004 |

| materials: | Rubber magnets |

| shape: | any shape |

| Production Capacity: | 50 tons monthly |

| Packing: | according to customers is requirements |

| Delivery Date: | General delivery for 10 days |

Product Description

Applications of rubber: magnetic separation, magnetic lifters, sucking discos, magnetic valves, magnetic drivers, magnetic bearing.

Applications of rubber blocks: magnetic bookmarks, magnetic photo frames, magnetic puzzle maps, magnetic erasable drawing boards, magnetic phonebooks, magnetic darts, various kinds of fridge magnet.

Introduction

Constitution: compound material of ferrite magnetic particles and synthetic rubber

Production: squeezing or rolling and show good flexibility

Processing: can be any forms and specifications

Application: applied in electric motors, refrigerators, toys and printing.

Constitution: compound material of ferrite magnetic particles and synthetic rubber

Production: squeezing or rolling and show good flexibility

Processing: can be any forms and specifications

Application: applied in electric motors, refrigerators, toys and printing.

Rubber Magnet

Rubber magnet, also called bonded ferrite magnet, consists of bonded ferrite powder, rubber or plastics and other materials. It is made by squeezing, rolling or molding. Due to high plasticity, finished products or semi-products can be cut, punctured, length cut and mounted by other materials. They can resist corrosion and are hard to be demagnetized. There are two classifications—isotropic rubber magnet and anisotropic rubber magnet. Isotropic rubber magnet has relatively poor magnetism and has been used in fridges, printing and promoting commodities. While the magnetism of anisotropic rubber magnet is so strong that it can be applied in mini-motors, computers, laser printers, copiers and magnetic toys.

Advantages:

Rubber magnet, also called bonded ferrite magnet, consists of bonded ferrite powder, rubber or plastics and other materials. It is made by squeezing, rolling or molding. Due to high plasticity, finished products or semi-products can be cut, punctured, length cut and mounted by other materials. They can resist corrosion and are hard to be demagnetized. There are two classifications—isotropic rubber magnet and anisotropic rubber magnet. Isotropic rubber magnet has relatively poor magnetism and has been used in fridges, printing and promoting commodities. While the magnetism of anisotropic rubber magnet is so strong that it can be applied in mini-motors, computers, laser printers, copiers and magnetic toys.

Advantages:

- In order to promote healthy development of environmental protection, our materials are in accordance with standards of International Environmental Organizations.

- Our main production facilities are introduced from Italy and Japan.

- Our magnetic powders are made by ourselves, which lower our cost and strengthens our competition on price.

- We can manufacture any shape of rubber magnet according to customers' requirements. The surface of the magnet can be mounted by glue, pvc, four-color printings, double-sided adhesive, sponge, silver.

- We can manufacture any molds of knifes, plastics and metals.

- Products rights of will be firmly protected because every product or mold is designated for certain customers

- We are one of the influential manufacturers of rubber magnets.

Process flow sheets

Test for raw material entered → magnetic powdering → rubber → combination of materials →squeezing→ products assembly → post processing/cleaning → mounting/labeling/magnetizing → product testing → finished product –

Test for raw material entered → magnetic powdering → rubber → combination of materials →squeezing→ products assembly → post processing/cleaning → mounting/labeling/magnetizing → product testing → finished product –

GRADE | Br | HCB | HCJ | (BH)max |

YN-5T | 140-155 1400-1550 | 90-120 (1125-1500) | 130 (1625) | 4.0-5.6 (0.5-0.7) |

YN -8 | 160-185 (1600-1850) | 120-140 (1500-1750) | 150 (1875) | 5.6-7.0 (0.7-0.89) |

YN -10 | 200-210 (2000-2100) | 145 (1812) | 160 (2000) | 8.0-9.6 (1.0-1.2) |

YN -11 | 230-245 (2300-245) | 160 (2000) | 175 (2188) | 10.0-11.0 (1.25-1.39) |

YN -13 | 250 (2500) | 160 (2000) | 182 (2275) | 11.2-12.6 (1.40-1.51) |

YN -15 | 260 (2600) | 172 (2150) | 196 (2450) | 12-12.8 (1.5-1.6) |

YN -11H | 230-240 (230-2400) | 170 (2125) | 188 (2500) | 10.0-11.0 (1.25-1.34) |