High Quality Cylinder ALNICO magnets

| Min. Order: | 100 Kilogram |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20 tons monthly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Sintering NdFeB Block, NdFeB Ring Magnet, Irregular Magnet, Disk NdFeB Magnet, Ferrite Sphere Magnet |

Product Detail

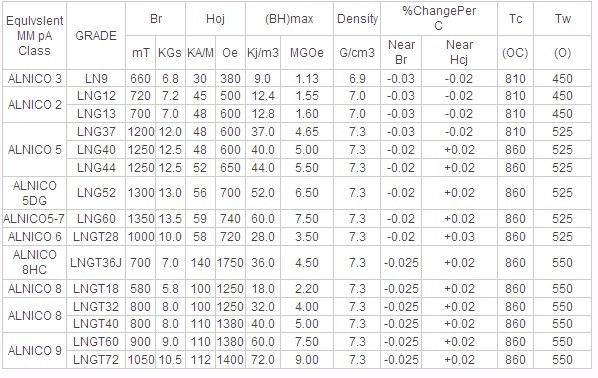

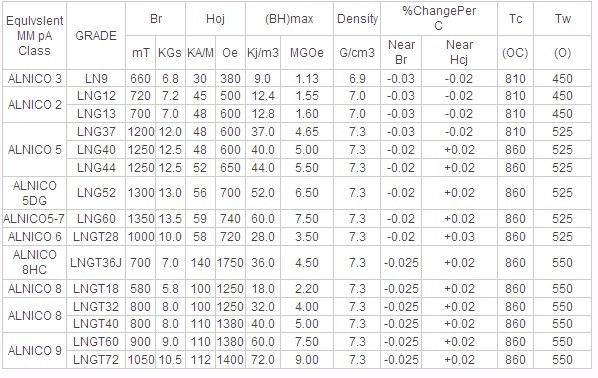

| Model No.: | LN9 LNG12/13/37/40/44/52/60 LNGT28/18/32/40/60/36J |

|---|---|

| Means of Transport: | Ocean, Air |

| certificate: | ISO9001:2000 , ISO 14001:2004 |

| materials: | AlNiCo |

| shape: | cylinder |

| Production Capacity: | 20 tons monthly |

| Packing: | occording to customers is requiements |

| Delivery Date: | General deliverly for 10 days |

Product Description

Cylindrical AlNiCo can be applied in magnetic latching relay, watt-hour meters, water meters, counters, reed switch and sensors.

2. High working temp: 450-550 degree

Cast Alnico magners,red spray-paint Alnico magnets,cylinder cast Alnico magnets

1. Many Grades: AlNiCo2/5/8/92. High working temp: 450-550 degree

3. High energy and relatively low coercivity

4. Excellent ability to withstand extreme temperatures stability

5. Widely used in instruments and meters: volt-amp meters; watt bour meters; medical instruments.

5. Widely used in instruments and meters: volt-amp meters; watt bour meters; medical instruments.

6. Products manufactured according to ISO9001 quality system.

7. The magnetic properties are very stable in chance of the temperature (-0.02%/°C for Br)

8. The max operation temperature is 550 degree centigrade.It is ideal for the high temperature applications.

9. The magnet has good corrosion resistance.

10. High mechanical strength

11. Various shapes and sizes or according to customers' request

12. High quality with competitive prices.

13. Used in different applications,such as speaker,mobile odometer,eletricitymeter,watermeter,eletricity motor switch adhesion sensors and so on.

Cast Alnico is manufactured by pouring a molten metal alloy into a mold and then further processing it through various heat-treat cycles. The resulting magnet has a dark gray exterior appearance, and may have a rough surface. Machined surfaces have a shiny appearance similar to steel.

Process Flow: Raw Material-Mixing-Melting-Heat Treatment-Magnetic Testing-Grinding-Inspection-Packing and Shipping

Cast Alnico is manufactured by pouring a molten metal alloy into a mold and then further processing it through various heat-treat cycles. The resulting magnet has a dark gray exterior appearance, and may have a rough surface. Machined surfaces have a shiny appearance similar to steel.

Process Flow: Raw Material-Mixing-Melting-Heat Treatment-Magnetic Testing-Grinding-Inspection-Packing and Shipping

.jpg)