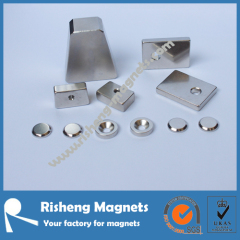

Neodymium Irregular Magnets

| Min. Order: | 8000 USD |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 1,500Tons NdFeB magnets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rare Earth Magnets, Magnetic Name Badge Holders, Permanent Magnetic Lifters, Neodymium Pot Magnets, Magnetic Catches |

Product Detail

| Model No.: | NIM-001 |

|---|---|

| Means of Transport: | Ocean, Air |

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Others |

| Composite: | Neodymium Magnet |

| Brand Name: | MJM |

| Material: | Neodymium, Iron, Boron, other elements |

| Application: | Motors, Speakers, Seperators |

| Grade: | 35MGOe-52MGOe |

| Coating/Plating: | NiCuNi |

| Export Area: | Germany, Italy, France, UK, USA & Asia |

| HS Code: | 8505111000 |

| Production Capacity: | 1,500Tons NdFeB magnets |

| Packing: | Plastic bags, cartons, pallets |

| Delivery Date: | 15-30 days |

Product Description

Description

Material: NdFeB, Grade 33MGOe to 52MGOe

Dimensions: Almost any size and shape

Tolerance: +/-0.1mm

Plating/Coating: Can be NiCuNi, Zn, Epoxy, Gold and Silver etc.

Magnetization Direction: Axially magnetized

Weight:

Surface Gauss:

Max. Working Temperature: 80ºC-200ºC

Brmax: 14,800 Gauss

BHmax: 52MGOe

Neodymium(NdFeB) magnets are made from Neodymium, iron, boron(Nd2Fe14B) and few other rare earth elements under four main production processes-raw material melting/powder making/mould pressing/sintering-to become the semi-finished products that will finally be machined and coated to be the finished parts. The main characteristics: 1)higher remanence(Br); 2)higher Coercivity(Hci) and energy product(BH); 3)lower Curie temperature(Tc). The main Applications: wind generators, DC motors, servo motors, air conditioners, medical equipment, VCM, mobile phones, speakers and magnetic holding and seperation systems etc.

Production Facilities

Melting Furnaces-25Kgs Capacity(9)/100Kgs Capacity(1)

Melt Spun Furnace(1)- 600Kgs Capacity

Airflow Milling Machines(3)

Moulding Machines- 30Tons(6)/60Tons(6)

Isostatic Press Machines(2)

Sintering Furnaces(10)- 300Kgs Capacity

Crushing Machines(2)

Cutting Machines(50)

Drilling Machines(15)

Grinder Machines- External Grinder(4)/Internal Grinder(3)/Ground Grinder(3)

Wire Cutting Machines(30)

Lathe Machines(10)

Break Corner Machines(8)

Plating/Coating Production Lines- NiCuNi Coating Line(1)/Zn9Trivalent) Coating Line(1)/Epoxy Coating Line(1)

Inspections Before Shipment

Criteria: GB/T2828, AOL Sampling Program

Quality Management: Referring to ISO 9001:2008

Magnetic Property(Demagnetization Curve) Test

Sizes and Tolerances Inspection

Magnetic Flux Test

Surface Gauss Test

Plating/Coating thickness Test

Salt Spray Test

others

Packaging & Delivery

Magnets that only passed inspections will be packed and shipped to our customer.

Production will usually take 15-30 days for an order. Delivery will take another 15-30 days by sea shipment to America and Europe customers.

If you are interested in our products, please feel free to contact us.We won't let you down.