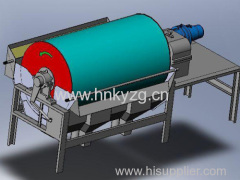

This type of magnetic separator is used to protect, clean and separate materials on applications mainly in the recycling and quarrying industry where it would be positioned either inline over the head pulley or across a conveyor belt. They are most commonly used on mobile crushing machinery. Through eye bolts they can be easily mounted at the top of the frame. The ferrous contaminants are conveyed to the side of the conveyor and are discharged to a collection bin by the cleated belts. Crossbelt magnetic separators can be mounted perpendicular to the material flow or over the head pulley parallel to the material flow. Crossbelt magnetic separators consist of rubber conveyor belts or stainless steel belts, adjustable take-ups, rugged steel channel frame and a shaft mounted speed reducer with direct drive motor.

.jpg)