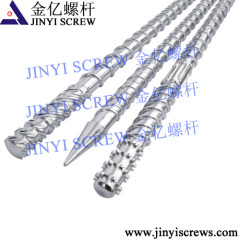

Extrusion Feed Screw Designs

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 1500 pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Barrier Design Screw Barrel, Egan Mixer Screw Design, Injection Machine Torpedo Tip, Grooved Force Feeding Barrel, Bimetallic Screw & Barrel |

Product Detail

| Model No.: | N/A |

|---|---|

| Means of Transport: | Ocean, Air, TNT |

| Shaft Design: | Single |

| Brand Name: | JINYI |

| Appliance: | Extrusion Equipment |

| Production Capacity: | 1500 pcs/month |

| Packing: | Wooden Case |

| Delivery Date: | 25 Days |

Product Description

Description:

Extrusion Screw is part of all kinds of plastic extrusion equipment, and provide essential function of plastication effect. No matter you are using extruder line, blowing line or pelletizing line, better designed & durable screw is most important for your precise product manufacturing.

Comparing to barrel, screw is smaller but have much more precise requirement for the design & material, that's why you need to choose an experienced supplier and durable material for your machine.

Advantage & Benefit:

1. Best solution, no matter you want to fix your old screw or replacing new screws, in here we offer you the best options

2. Superior design, our technial department has over 10 years' experience in designing for all kinds of appliance, better design guarantee your perfect running

3. Optional material, whether you are running virgin material or recycling material, we offer you different material for different use

4. After-sale consult, anything you met while using, our technial team is at your service for any probelm you may met.

Material List:

| JINYI | Chinese | Japan | America | German | Treatment | Hardness | Appliance |

| GB | JIS | AISI/SAE | DIN | ||||

| JYN1 | 38CrMoAl | SACM645 | 6470E | 41CrAlMo7 | Gas Nitrition | HV 950-1000 | Common Use |

| JYN2 | 40Cr | SCr440 | 5140 | 1.7035 | Chrome-plate | HRC 42-55 | |

| JYN3 | 42CrMo | SCM440 | 4140 | 1.7223 | Chrome-plate | HRC 48-58 | |

| JYN4 | 45# | S45C | 1045 | 1.1191 | Hardening | HRC 42-46 | |

| JYH5 | Cr12Mo1V | SKD11 | D2 | 1.2379 | Hardening | HRC 62-65 | |

| JYH6 | 4Cr5MoSiV1 | SKD61 | H13 | 1.2344 | Hardening | HRC 60-65 | |

| JYH7 | 9Cr18MoV | SUS440B | 440B | 1.4112 | Hardening | HRC 56-58 | |

| JYG1 | (Confidential) | <35% GF | |||||

| JYG2 | <40% GF | ||||||

| JYG3 | <40% GF | ||||||

| JYG4 | <45% GF | ||||||

| JYG5 | <50% GF | ||||||

| JYG6 | >50% GF | ||||||

| JYG7 | Optical Glass | ||||||

| JYG8 | >300℃ Temp. | ||||||