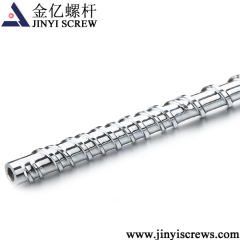

Tederic TR80 Screw Barrel with SKD61 Hardened

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 800 Sets Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Barrier Design Screw Barrel, Egan Mixer Screw Design, Injection Machine Torpedo Tip, Grooved Force Feeding Barrel, Bimetallic Screw & Barrel |

Product Detail

| Model No.: | N/A |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | JINYI |

| Power: | 0 |

| Capacity: | 0 |

| Material: | SKD61 |

| Treatment: | Hardened |

| Suitable for: | 30 Glass Fiber |

| Feature: | Super Anti-abrasion |

| Guarantee: | 1 Year |

| Delivery time: | 15-20 days |

| Service: | 24H online |

| Production Capacity: | 800 Sets Per Month |

| Packing: | Wooden Case |

| Delivery Date: | 20 Working Days |

Product Description

Introduction:

Stainless Steel Screw Barrel is made with steel 9Cr18MoV, 304 & 316 and hardened to adapt the high corrosive, transparent or Food industry.Due to its superior performance compare to normal nitrided or bimetallic material, it's now commonly used in much area

Our Advantage:

1.Professional Equipment

We are equiped with automatic CNC Turning & Milling Machine,Long-Deep Boring Machine, Max. 10m Depth Nitriding Equipment, which all ensure the machining precision.

2.Precision Machining

With our long-term history, many skilled works have formed our strong power & ensure the quality of final product

3.Advanced Design

Combined with all kinds of mixer design, can meet the varies demand for different plastics.

Material Choice:

9Cr18MoV

AISI-304

AISI-316

Hardness: 40-55HRC Depends on Material Choose

Rest Material Available

| JINYI | Chinese | Japan | America | German | Treatment | Hardness | Appliance |

| GB | JIS | AISI/SAE | DIN | ||||

| JYN1 | 38CrMoAl | SACM645 | 6470E | 41CrAlMo7 | Gas Nitrition | HV 950-1000 | Common Use |

| JYN2 | 40Cr | SCr440 | 5140 | 1.7035 | Chrome-plate | HRC 42-55 | |

| JYN3 | 42CrMo | SCM440 | 4140 | 1.7223 | Chrome-plate | HRC 48-58 | |

| JYN4 | 45# | S45C | 1045 | 1.1191 | Hardening | HRC 42-46 | |

| JYH5 | Cr12Mo1V | SKD11 | D2 | 1.2379 | Hardening | HRC 62-65 | |

| JYH6 | 4Cr5MoSiV1 | SKD61 | H13 | 1.2344 | Hardening | HRC 60-65 | |

| JYH7 | 9Cr18MoV | SUS440B | 440B | 1.4112 | Hardening | HRC 56-58 | |

| JYG1 | (Confidential) | <35% GF | |||||

| JYG2 | <40% GF | ||||||

| JYG3 | <40% GF | ||||||

| JYG4 | <45% GF | ||||||

| JYG5 | <50% GF | ||||||

| JYG6 | >50% GF | ||||||

| JYG7 | Optical Glass | ||||||

| JYG8 | >300℃ Temp. | ||||||