CNC Continuous Sponge Foaming Equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Jiangmen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Semi Automatic Foaming Machine, Auto Foam Batching Machine, Mattress Motorized Rolling Conveyor, CNC Glue Machinery (high Efficiency), Automatic Mattress Roll-Packing Machine |

Product Detail

| Model No.: | SL-08FC |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Softlife |

| Chemical: | 12groups |

| Foaming type: | Trough foaming/Spray foaming |

| Speed of mixing: | ≤5000rpm/ min |

| Over length: | 12.5M |

| Fall plate: | 6 steps total 6.25M |

| Conveyor length: | 18M |

| Foam width: | 1.3-2.25m |

| Foam height: | ≤1.25M |

| Foming speed: | ≤8m/min |

| Max output: | 250kgs/min |

| Production Capacity: | 100 sets |

| Packing: | Pearl cotton & PVC film |

| Delivery Date: | 60 days |

Product Description

SL-08FC CNC Continuous Foaming Machine

This machine can be used for continuous producing Flexible Polyurethane Foam(maxfoam), which density is 9~50KGS/M³. It can be automatic cutting the foam into difference sizes which is according to client's requirement. It can be realized numerical control with accurate and convenient ration during the whole production. It becomes more easily and stable to operate the machine.

Computerized control system

It can be realized numerical control during the whole production. It is very easy to operate with its humanization consideration design. It is able to store 100 formulations in advance.

Automatic formulation function

The computer can be automatic to generate formulation for your reference and calculate the dosage of material if you input the density and color which you need. The computer can be automatic to check if the formulation is correct when you give the input of material.

Costing function

The computer can be automatic to display the input of chemical material and the output of foams in each foaming produce.

Printing function

All information including the formulation, the input of chemical material and the output of foams can be printed. The exact data can be used to strengthen management.

Electronic metering system

The metering system is adopted the advance electronic metering pumps from U.S.A. and the monitoring equipment. Through computer, it can display formulation's dosage of 12 groups' chemical material and actual supply in figure or diagram. The metering system can be automatic to adjust it with great precision when the actual supply cannot meet the formulation requirement. It is the base to produce the good foam and to reduce the unnecessary wastage with this function.

High speed mixing system

It adopts two steps mixing with low-pressure and high-speed. This can make the foam's air hole fine and smooth. It presets cycle cooling and automatic cleaning functions.

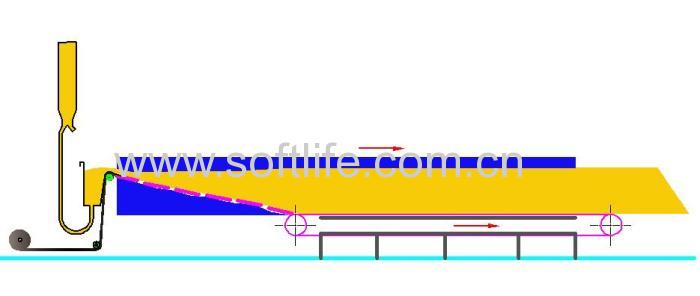

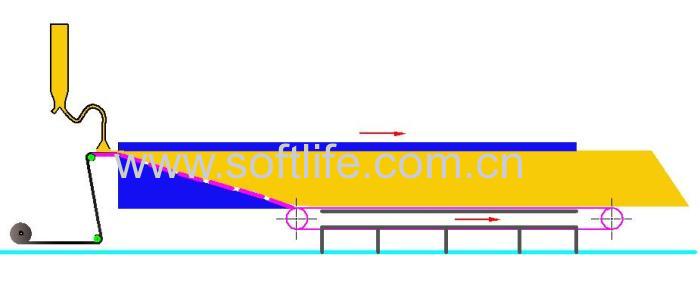

Adjustable oven system

The width of two moving side wall can be adjusted for producing difference width foam. The height of six steps raising platform can be adjusted for producing difference density foam.

Automatic cutting system

It is computerized control. It can be changing the cutting length in any time. The degree of accuracy can be equal or less than 1mm.

Automatic thermostat apparatus (optional)

It can maintain the suitable temperature of chemical material in order to producing high quality foam.

Technical Specification:

Model | SL-08FC |

Chemical | 12groups |

Foaming type | Trough foaming/ Spray foaming |

Speed of mixing | ≤5000rpm/ min |

Over length | 12.5M |

Fall plate | 6 steps total 6.25M |

Conveyor length | 18M |

Foam width | 1.3-2.25m |

Foam height | ≤1.25M |

Foming speed | ≤8m/min |

Max output | 250kgs/min |

Total power | 70.85KW |

Dimension | 38m(L)×4.5m(W)×4m(H) |