CONTINUOUS POCKET SPRING MAKING LINE

40000.0~55000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100SETS |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Jiangmen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Semi Automatic Foaming Machine, Auto Foam Batching Machine, Mattress Motorized Rolling Conveyor, CNC Glue Machinery (high Efficiency), Automatic Mattress Roll-Packing Machine |

Product Detail

| Model No.: | sl-12PA-1 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | SOFTLIFE |

| TYPE OF SPRING: | BARREL / CYLINDRICAL |

| SPRING DIAMETER: | @1.8--2.2MM |

| SPRING CIRCLE: | 5--10 circle |

| Max output: | 70 coils/min |

| Power: | 25KW |

| Spring type: | POCKET SPRING |

| Motor control: | SERVO MOTOR |

| Pocket material: | NON-WOVEN |

| Pocket welding type: | MIDDLE WELDING METHOD |

| Up and down non-woven system: | with |

| Production Capacity: | 100SETS |

| Packing: | Export PVC film |

| Delivery Date: | 50 days |

Product Description

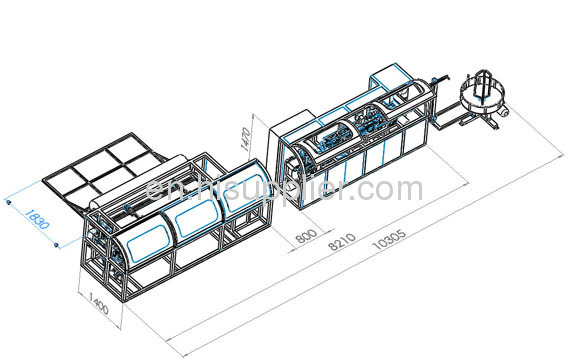

SL-12PA POCKET SPRING PRODCUTION LINE

1.In the production line by the SL-12 P auto pocket spring machine and SL-12A auto pocket spring assembling machine is composed of two parts.

2 with automatic control technology, from production to the whole of bagged spring mattress production, by the machine automatically.

3 having upper and lower adhesive function.

4 has the advantages of convenient operation, high efficiency, low noise.

5 production lines has compact and simple structure, greatly reduces the occupied space of workshop, than similar products with high performance price ratio.

6 machine movement is smooth and accurate, high working stability.

7 control parameters can be based on customer requirements to set, in order to meet customer demand for product diversification

8 producing mattress has simple appearance, generous, comfortable degree higher characteristic.

9 materials used automatically shutdown.

1.In the production line by the SL-12 P auto pocket spring machine and SL-12A auto pocket spring assembling machine is composed of two parts.

2 with automatic control technology, from production to the whole of bagged spring mattress production, by the machine automatically.

3 having upper and lower adhesive function.

4 has the advantages of convenient operation, high efficiency, low noise.

5 production lines has compact and simple structure, greatly reduces the occupied space of workshop, than similar products with high performance price ratio.

6 machine movement is smooth and accurate, high working stability.

7 control parameters can be based on customer requirements to set, in order to meet customer demand for product diversification

8 producing mattress has simple appearance, generous, comfortable degree higher characteristic.

9 materials used automatically shutdown.

Main technical parameters:

Machine size ( length * width * height ) | 10.5× 1.4 × 1.5m (not including the table ) |

| Machine components | Independent bagged spring machine ( 1 ) + automatic glue machine (1 units ) |

Spring shape | Drum / cylindrical |

Diameter of spring | The first end of φ 45-60mm,φ60-80 |

The length of the spring ( into the bag after ) | 125-180mm |

Wire diameter | φ1.8-φ2.2mm |

Fabric width | 410-520mm |

Welding mode | Ultrasonic welding |

Production efficiency | 65 pcs/min |

Total power | 21 kw |

Compressed air pressure | 6kg/cm3 |

Total weight | 3.3t |