20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 200Sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | DRB-L Series -211004 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Certification: | Others |

| Brand Name: | EGMEC |

| Product: | DRB Series of lubrication electric grease pump controlled by a directional valve with 200bar operation pressure |

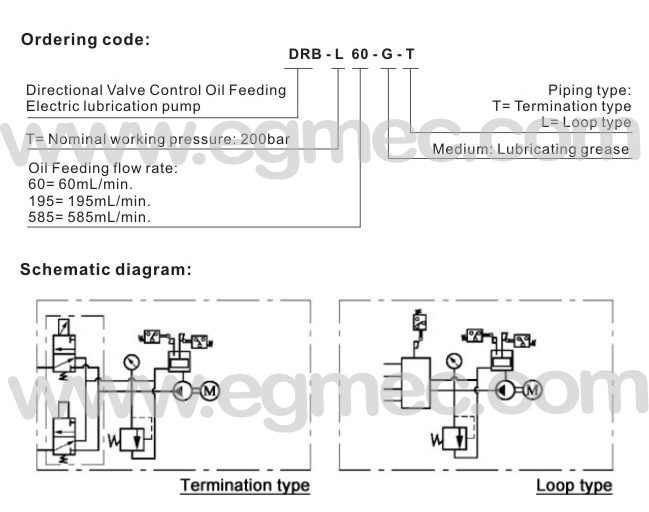

| Ordering code: | DRB-L60Z-H series |

| Max. pressure: | 20MPa |

| Tank Volume: | 20-90L |

| Power: | 0.37-1.5KW |

| Nominal flow: | 60-585ml/min |

| Warranty: | One year |

| Medium: | Grease |

| Quality control: | 100% standard testing |

| OEM and ODM: | Please contact us |

| Production Capacity: | 200Sets |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

The item DRB-L Electric Grease Pump is for lubrication points, wide distribution, high frequency double the oil dry oil lubrication system, as a distributor through the lane for the delivery of grease to lubricate parts, which can meet the needs of a variety of machinery and equipment, production lines for large units and is particularly suitable.

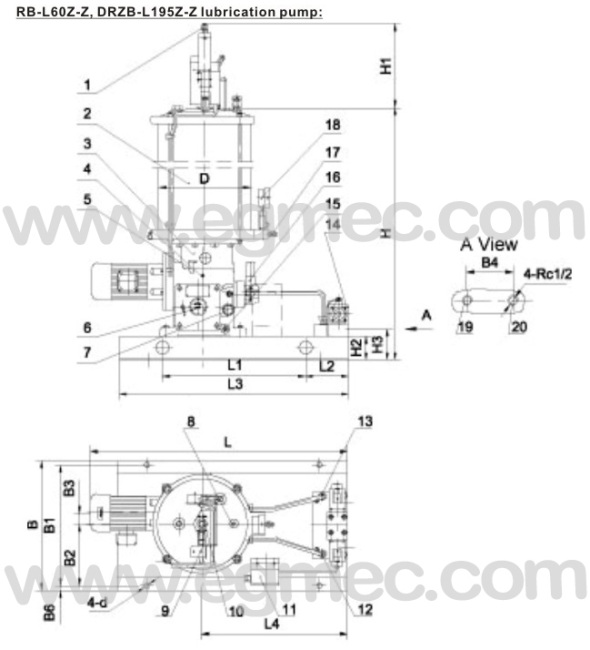

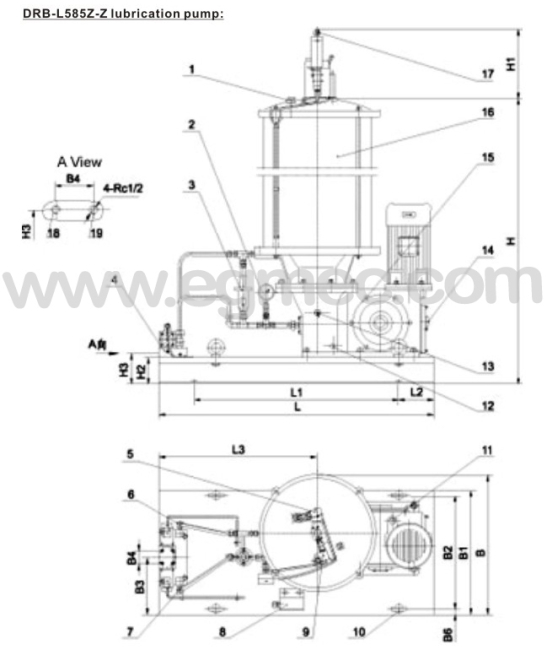

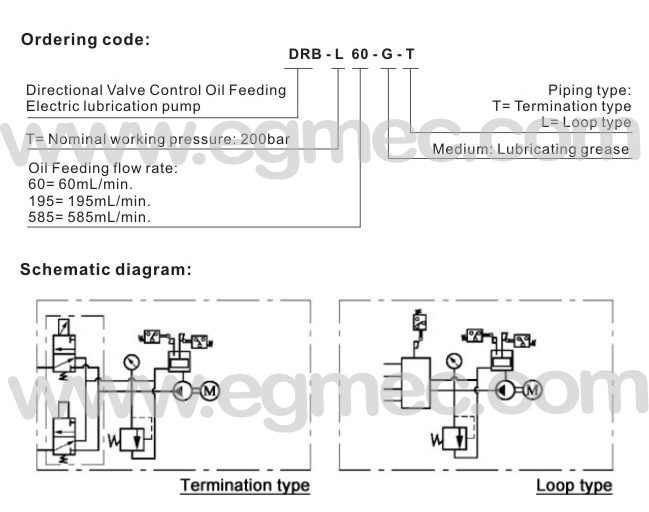

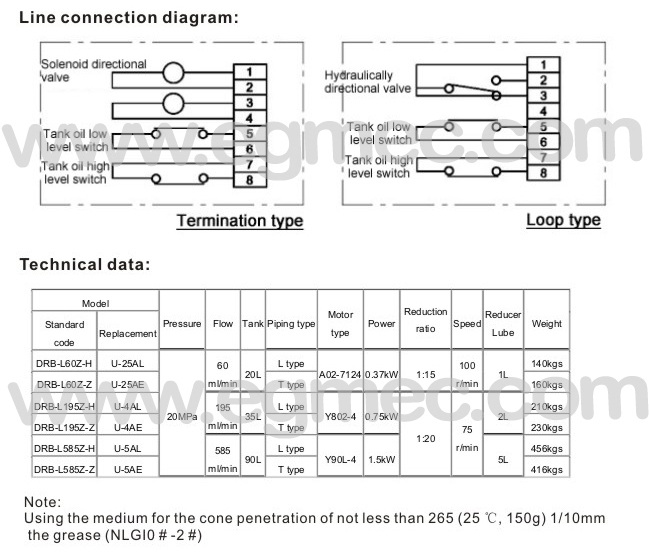

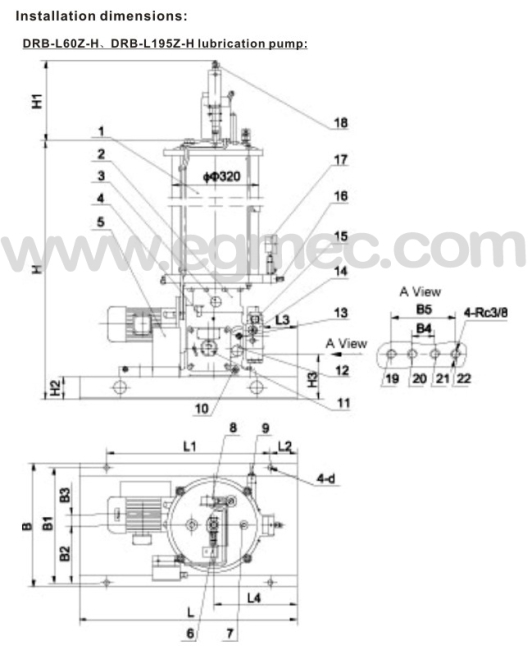

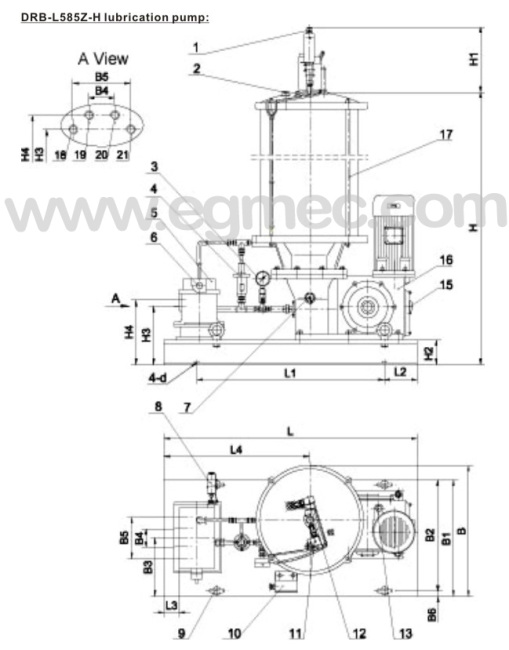

The series of 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump to form a double-ring lubrication system, which ring system composed of competent road layout, the back end of the lubrication channel charge pump to control the hydraulic system pressure valve, alternately to the two in charge of Road Feeding centralized grease lubrication system; see the outline drawing and dimensions table in the regulations, in which can also be composed of two-terminal-type lubrication system, that is, the pressure from the mains at the end of the electromagnetic control valve to control. Valve alternately to the two main channel for the delivery of centralized grease lubrication system, but also see the outlines and dimensions requirements. The series of 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump with double plunger body, reliable operation, gear box placed in the pump body, compact structure, small size, coupled with the corresponding electronic control box can be automatically controlled.

The working principle of 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump:

The series of 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump is assembled by the piston, oil storage device, valve, motor and other components. In the motor-driven piston pump, the grease from the inhalation of oil storage device, the pressure to the valve, valve alternately by the two oil ports along the transmission went out, when a grease oil pressure delivery port when the Another oil port and oil storage device connected to unloading. Ring structure of electric lubrication pump with hydraulic valve, four interfaces, an external director of two oil pipeline were brought back from the two for the return pipe, relying on the oil return pipe valve for the hydraulic drive .

Terminal structure of electric lubrication pump with electromagnetic valve, there are two interfaces, an external two oil executives, rely on the pros and cons electromagnet to supply power to achieve change

How to use 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump:

1.The 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump should be installed right in the ambient temperature, dust, less vibration, easy adjustment, inspection, maintenance and back-fat convenience and wherever possible be located where the center of the system, shorten the length of pipes to maintain a minimum pressure drop so that the pump can generate enough pressure to overcome the resistance of lubrication points.

2.The use of the slowdown before the first piston chamber to join N220 industrial gear oil to the provisions of liquid oil standard.

3.Inside the oil storage DJB-V70 complement fat using electric pumps lubrication pump supplies from the mouth up into, the use of grease should be clean, does not allow mixed with dirt.

4.Lubrication pump rotation direction is one-way, must be used by the motor rotating the rotation to the licensing requirements to use the connection.

5.The pump pressure relief valve in the standard setting 23MPa, 0 ~ 20MPa can be adjusted within the range, the pump when in use does not allow more than nominal pressure of 15% (23MPa).

6.Central lubrication pump of the hydraulic valve set pressure by 5MPa it is set.

7.The series of electric lubrication pump for indoor installation type, outdoors or in harsh environment applications use, must take protective measures.

20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump

How to order 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump:

1. The Electric Grease Pump used the following four types of standard electronic control box can be selected according to different control requirements.

1.1 DEA-2E-type terminal-type electric control box

1.2 DEA-2L-type ring-type electric control box

1.3 R1902 resin ring with a complement control electronic control box

1.4 R1904-type terminal-type complement lipid control with electronic control box

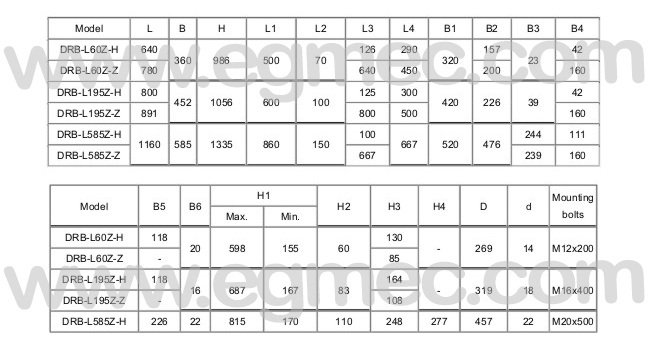

2. The 20Mpa/2900psi Pressure Directional Valve Control Lubrication Electric Grease Pump order sub-component pump selection and dimensions table as below: