Cartridge Type Poppet Spool Stainless Hydraulic Check Valve

13.0~21.23 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 25000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | CVP22 Series -111005 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Power: | Hydraulic |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Check |

| Material: | Alloy |

| Temperature of Media: | High Temperature |

| Media: | Oil |

| Brand Name: | EGMEC |

| Product: | Cartridge poppet check valves |

| Description: | Poppet check valve, thread connection |

| Max. flow: | 112L/min. |

| Max. work pressure: | 240bar |

| Medium: | Mineral oil or others relevant |

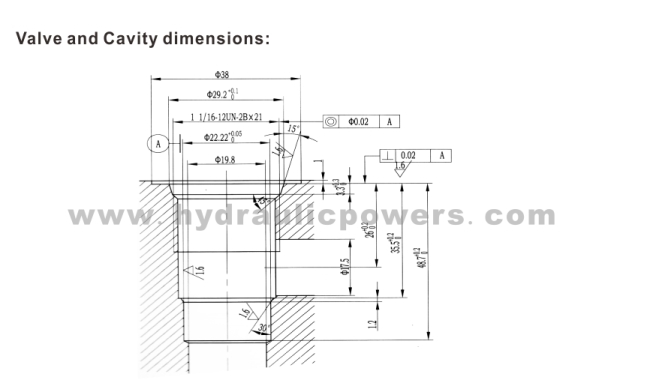

| Connection threaded: | 1 1/16-12UNF |

| Quality tested: | High pressure and leakage testing |

| Superficial surface: | White zinc, Color zinc plating, Chrome plated |

| Customized: | Available, as per drawings or samples offered |

| OEM/ODM: | Acceptable for any parts |

| Production Capacity: | 25000 |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

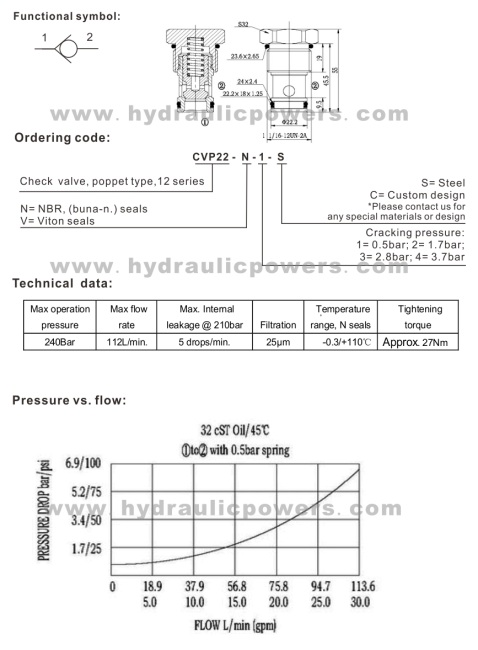

The CVP22 Series of Cartridge Type Poppet Spool Stainless Hydraulic Check Valve has the good operation characteristics:

1.Keep up the pressure. The directional valve has a slide leakage gap, only a short time to maintain pressure, when maintain pressure requirements, which can be coupled with one-way valve in the oil circuit, using the poppet valve is closed tightly, so that long pressure maintenance can be obtained.

2.For supporting the cylinder, in the vertical hydraulic cylinder poppet valves and pipes due to leakage in the piston and piston abundance if the heavy may cause piston and piston rod down. The cartridge type poppet spool stainless hydraulic check valve chamber connected to the circuit under the hydraulic cylinder, hydraulic cylinder can be preventing such activities as part of the piston and slide down.

3.For hydraulic cylinder lock. When the directional valve is in the meddle position, the poppet cartridge check valve is closed, the two can be tightly closed chamber of the oil hydraulic cylinder, when the piston can't move because of external force generated.

Any custom design of poppet cartridge check valve are available, we will design, choose the suitable materials, checking proper working characteristics, testing working operation and service life for our regular customers, please contact us for more details.

Rated flow capacity:112 L/MIN

Internal leakage: ≤3ml/min

Recommended filtration: 25 MICRON

Hydraulic fluids: Mineral Oil, Viscosity 10 - 400 cST

Temperature range: -30° C to +110° C

Note: For extension of the service life, It is better to use the condition where is no gas or dust in ambient which can corrupt metal or destroy nonconductor

Please contact us for any special products.

Poppet cartridge check valve technical data as follow;

Valve and cavity installation dimensions: