10Mpa Low Pressure 60-195ml/min High Flow Rate Single Line Electric Grease Lubrication Pump

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 350 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | DRB-J Series -211008 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Certification: | Others |

| Brand Name: | EGMEC |

| Product: | DRB Series of 100bar Low pressure, 0.375Kw -0.75Kw power motor, single single line electric grease lubrication pump |

| Relatively Model: | DRB-J60Y-H = U-25DL; DRB-J195Y-H = U-4DL |

| Nominal pressure rate: | 100bar |

| Nominal flow rate: | 60ml/min. or 195 ml/min. |

| Speed: | 75 r/min or 100 r/min |

| Grease tank volume: | 16L or 26L |

| Motor power supply: | 0.37kw or 0.75 kw |

| Piping type: | Circle type |

| Accumulator volume: | 50mL |

| Medium: | 120CST lubricating grease viscosity value of not less than |

| Production Capacity: | 350 |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

Brief introduction:

DRB-J series electric grease lubrication pump is designed for nominal pressure 10MPa the two- jet concentrated

lubrication system, electric lubrication pump output lubricants assigned two distributor quantitative evacuation

Automatically by the input hydraulic pressure to the injection valve to open the check valve of the compressed air line to the lubricating oil –shaped oil and gas mist spray to the friction of the machinery and equipment parts.

DRB-J series electric grease lubrication pump is designed for nominal pressure 10MPa the two- jet concentrated

lubrication system, electric lubrication pump output lubricants assigned two distributor quantitative evacuation

Automatically by the input hydraulic pressure to the injection valve to open the check valve of the compressed air line to the lubricating oil –shaped oil and gas mist spray to the friction of the machinery and equipment parts.

It is particularly suitable for open gears pass dynamic the machine friction parts of the gear tooth surface, supporting roller , sliding rail surface lubrication.

10Mpa Low Pressure 60-195ml/min High Flow Rate Single Line Electric Grease Lubrication Pump

10Mpa Low Pressure 60-195ml/min High Flow Rate Single Line Electric Grease Lubrication Pump

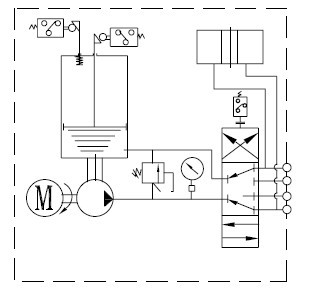

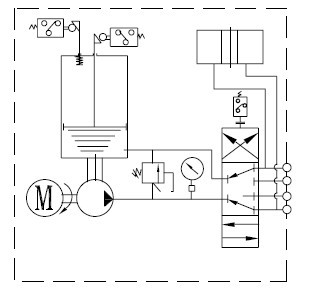

The DRB-J series electric grease lubrication pump is made up of oil reservoir, hydraulic valve, accumulator, electric motors and other components.

Piston pump motor drive from oil storage inhalation lubricating oil pressure to the hydraulic valve, valve has four interfaces, connect to external two oil pipes, and return pipes by main supplying pipe .

By hydraulic valve back to the oil pressure in the tubing to promote commutation alternately along two ports lubricating oil will be transported out, when an oil port pressure feed grease, and the other ports and oil storage is on unloading, the two ports of the accumulator with two valve oil exports and then so that the pipeline can be replenished in a timely manner for the change to the oil supply after the instant oil.

By hydraulic valve back to the oil pressure in the tubing to promote commutation alternately along two ports lubricating oil will be transported out, when an oil port pressure feed grease, and the other ports and oil storage is on unloading, the two ports of the accumulator with two valve oil exports and then so that the pipeline can be replenished in a timely manner for the change to the oil supply after the instant oil.

Symbol:

How to use the DRB-J series:

Ordering code:

DRB – J 60 Y -H

DRB= Single Line Grease Pump

J= Grease feeding 63mL/ min.

60= 60mL/min.

Y= Lubricating grease

H= Circle type

Technical data:

Model | Pressure rate (bar) | Grease feeding (mL/min.) | Reservoir volume (L) | Speed (r/min) | Accumulator (mL) | Motor power (kW) | Reduction ratio | Piping type | Reducer lubricant (L) | Weight (kg) | |

DRB-J60Y-H | U-25DL | 100 | 60 | 16 | 100 | 50 | 0.37 | 1 : 15 | Circle type | 1 | 140 |

DRB-J195Y-H | U-4DL | 195 | 26 | 75 | 0.75 | 1 : 20 | 2 | 210 | |||

The use of media for 120CST lubricating oil viscosity value of not less than.

How to use the DRB-J series:

1.The series of electric lubrication pump should be installed in a suitable ambient temperature, less dust, small vibration, ventilation, drying, and easy up the grease oil, adjustment, inspection and maintenance convenient occasion.

2.The use of the outdoor or harsh environmental conditions occasions, protective measures should be taken.

3.Filling oil in the oil reservoir, the DJB-V70 -type or DJB-V400 electric fuel pumps should be used, lubrication pump supply port injection. (Replenishment port built filter).

4.Reducer chamber to the pump lubrication pump operation before filling oil ( Industrial gear oils N220) to reach the required oil standard level the, reducer cavity lubricant put into use in the lubrication pump 200 hours, should be checked every 200 hours after replacement

5.Lubrication pump rotation direction is unidirectional, and must use the wiring to the licensing requirements of the spin motor rotation.

6.Pump relief valve set pressure can by changed in any adjustment in the range of 0 ~ 10MPa, nominal pressure in use does not allow more than 10 % ( 11MPa ).