.jpg)

POLYURETHANE MESH 0.5MM

35.0~73.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500pieces for one day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nylon Screen Clothes, Johnson Screen, Fiberglass Screen Netting, Centrifuge Wedge Wire Screen Basket, Stainless Steel Wire Cloth |

Product Detail

| Means of Transport: | EXPRESS, AIR, SEA |

|---|---|

| Application: | Filter |

| Material: | Others |

| Brand Name: | Tianshan |

| Production Capacity: | 500pieces for one day |

| Packing: | Wooden case |

| Delivery Date: | 15days |

Product Description

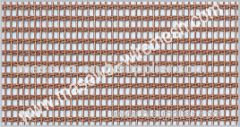

Polyurethane Sieve panel or mesh is developed in recent years for the mining beneficiation, grading, dehydration and other screening machines replace metal sieve (network) is a new product. Mainly used in coal, iron ore, copper, gold and other ores grading, screening, dehydration and other places, is one of the accessories necessary shaker sieve structure by polyurethane divided into four: mosaic Bolt link layering link connecting sieve hook.

For example, layering connection type: Please place the sieve surface of the sieve plate, and then sieve the support beam to install. Should generally be in the screening machine on both sides of the upper sieve plate, along with the width direction of the next material suitable u-long strips of iron suitable distance from drilling screw holes, then bolt and tighten the underlying support beam, so that sieve-plate jail firmly fixed in the middle. Support beams and long strips of iron and sieve plates of the contact surface is best to use rubber (can use old hose) pad. Sieve the middle support beam above method can also be installed here.

If the sieve plate is not required to install, might make it in the sieve surface of the upper and lower jitter, long-term friction with the steel support beam collisions, will seriously affect the life of sieve plates.

Article vertical and horizontal screen by the high wear-resistant polyurethane materials, as amended, containing wire. Service life than traditional metal mesh 3-10 times higher.

Unique structure, the appropriate elastic and plastic force, not only can reduce the card blocking, while the second harmonic due to screening of high-frequency vibration, but also reduce the sticky block. Practical hole high rate of screening efficiency.

Screen tensioning hook provides for flexibility on both sides, the overall light weight, good flexibility, transport storage easy installation and removal easy.

Screen can effectively absorb shock, reduce noise, improve the working environment.

For example, layering connection type: Please place the sieve surface of the sieve plate, and then sieve the support beam to install. Should generally be in the screening machine on both sides of the upper sieve plate, along with the width direction of the next material suitable u-long strips of iron suitable distance from drilling screw holes, then bolt and tighten the underlying support beam, so that sieve-plate jail firmly fixed in the middle. Support beams and long strips of iron and sieve plates of the contact surface is best to use rubber (can use old hose) pad. Sieve the middle support beam above method can also be installed here.

If the sieve plate is not required to install, might make it in the sieve surface of the upper and lower jitter, long-term friction with the steel support beam collisions, will seriously affect the life of sieve plates.

Article vertical and horizontal screen by the high wear-resistant polyurethane materials, as amended, containing wire. Service life than traditional metal mesh 3-10 times higher.

Unique structure, the appropriate elastic and plastic force, not only can reduce the card blocking, while the second harmonic due to screening of high-frequency vibration, but also reduce the sticky block. Practical hole high rate of screening efficiency.

Screen tensioning hook provides for flexibility on both sides, the overall light weight, good flexibility, transport storage easy installation and removal easy.

Screen can effectively absorb shock, reduce noise, improve the working environment.