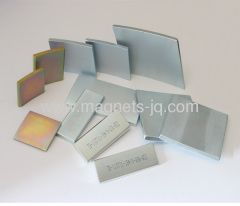

NdFeB motor magnet

10.0 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000000pcs per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Motor Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | able magnet |

| Composite: | NdFeB |

| Production Capacity: | 1000000pcs per month |

| Packing: | packing as client's request |

| Delivery Date: | Within 30 days |

Product Description

Product name:NdFeB motor magnet

NdFeB Magnetic

70X40mm

Weight 1.15KG

Nickel-plated (Ni-Cu-Ni)

Magnetisation: N35

Strength: Approx. 580 Kg

Extra strong (N35) magnets. These magnets are often used by model airplane builders. Heat resistant up to 80 degrees Celsius.

NdFeB Magnetic mainly comprised of neodymium, iron and boron, is the third generation of the rare-earth permanent magnets, Sintered NdFeB is the strongest permanent magnets in the world up to date, It has excellent properties of high remanence, coercivity, and Max. Energy product.

NdFeB Magnetic grade

N35, N38, N40, N42, N45, N48, N50, N52(Max. Operational temperature: 80c)

N33SH, N35SH, N38SH, N40SH, N42SH(Max. Operational temperature: 150c)

N28UH, N30UH, N33UH, N35UH, N38UH(Max. Operational temperature: Up to 180c)

N28EH, N30EH, N33EH, N35EH(Max. Operational temperature: Up to 200c)

N30AH, N33AH, N35AH(Max. Operational temperature: Up to 230c)

NdFeB Magnetic Outsanding product:

1). High performance: N52, N48M, 48SH, 42UH, 38EH, 33AH

2). High working temperature: The AH series with 40 k Oe super-high coervice force can replace SmCo magnets successfully.

3). High consistency: The cpk of Br and Hcj are much higher than 1.67 the consisitency of surface magnetic field and magnetic flux can be controlled with +/-1%

4). High Anti-corrosion: The sale spray test and humid heat test of the high anti-corrosion coating could be more than 1000 hours

5). Low weight loss

PCT: 130c, humidity 100%, vapor pressure 2.7 bar. 20 days, average low weight loss less than 2 mg/cm2

NdFeB Magnetic applications:

Loudspeakers, motor assemblies, windmill, Home appliance, acousics, communication equipment, toy, car, servomotor, step motor, DC motor and linear motor, mircrophones

Pros: Very strong hold when contacting another magnet or plain iron, very difficult to pull away (easy to slide however).

Pretty strong hold between two of these even with a couple of mm in between.

Cons: Would like thicker (and more powerful) versions. Sure u can stack these together but sometimes it's not the same thing.

Other Thoughts: Good for attaching thick stacks of paper to refrigerators etc or pinching together papers or textiles.

Bottomline: This is the one if you need strong cost-effective magnets

You are welcome to enquiry on our NdFeB Magnetic

70X40mm

Weight 1.15KG

Nickel-plated (Ni-Cu-Ni)

Magnetisation: N35

Strength: Approx. 580 Kg

Extra strong (N35) magnets. These magnets are often used by model airplane builders. Heat resistant up to 80 degrees Celsius.

NdFeB Magnetic mainly comprised of neodymium, iron and boron, is the third generation of the rare-earth permanent magnets, Sintered NdFeB is the strongest permanent magnets in the world up to date, It has excellent properties of high remanence, coercivity, and Max. Energy product.

NdFeB Magnetic grade

N35, N38, N40, N42, N45, N48, N50, N52(Max. Operational temperature: 80c)

N33SH, N35SH, N38SH, N40SH, N42SH(Max. Operational temperature: 150c)

N28UH, N30UH, N33UH, N35UH, N38UH(Max. Operational temperature: Up to 180c)

N28EH, N30EH, N33EH, N35EH(Max. Operational temperature: Up to 200c)

N30AH, N33AH, N35AH(Max. Operational temperature: Up to 230c)

NdFeB Magnetic Outsanding product:

1). High performance: N52, N48M, 48SH, 42UH, 38EH, 33AH

2). High working temperature: The AH series with 40 k Oe super-high coervice force can replace SmCo magnets successfully.

3). High consistency: The cpk of Br and Hcj are much higher than 1.67 the consisitency of surface magnetic field and magnetic flux can be controlled with +/-1%

4). High Anti-corrosion: The sale spray test and humid heat test of the high anti-corrosion coating could be more than 1000 hours

5). Low weight loss

PCT: 130c, humidity 100%, vapor pressure 2.7 bar. 20 days, average low weight loss less than 2 mg/cm2

NdFeB Magnetic applications:

Loudspeakers, motor assemblies, windmill, Home appliance, acousics, communication equipment, toy, car, servomotor, step motor, DC motor and linear motor, mircrophones

Pros: Very strong hold when contacting another magnet or plain iron, very difficult to pull away (easy to slide however).

Pretty strong hold between two of these even with a couple of mm in between.

Cons: Would like thicker (and more powerful) versions. Sure u can stack these together but sometimes it's not the same thing.

Other Thoughts: Good for attaching thick stacks of paper to refrigerators etc or pinching together papers or textiles.

Bottomline: This is the one if you need strong cost-effective magnets

You are welcome to enquiry on our NdFeB Magnetic

.jpg)